Ultimate Guide to Understanding Sealed Thrust Bearings and Their Applications

Sealed thrust bearings are essential components in various industrial applications, providing crucial support and stability to rotating shafts while minimizing friction and wear. According to a recent report by MarketsandMarkets, the global bearing market is projected to reach USD 80 billion by 2026, with a significant emphasis on the adoption of advanced bearing technologies, including sealed thrust bearings, due to their enhanced performance and reliability. These specialized bearings are designed to withstand axial load while ensuring contamination protection, thereby prolonging their operational life. The growing demand for high-efficiency machinery in sectors such as automotive, aerospace, and heavy industries further underscores the importance of understanding sealed thrust bearings and their applications. As industries strive for improvement in energy efficiency and equipment longevity, the role of sealed thrust bearings becomes increasingly vital in meeting these demands.

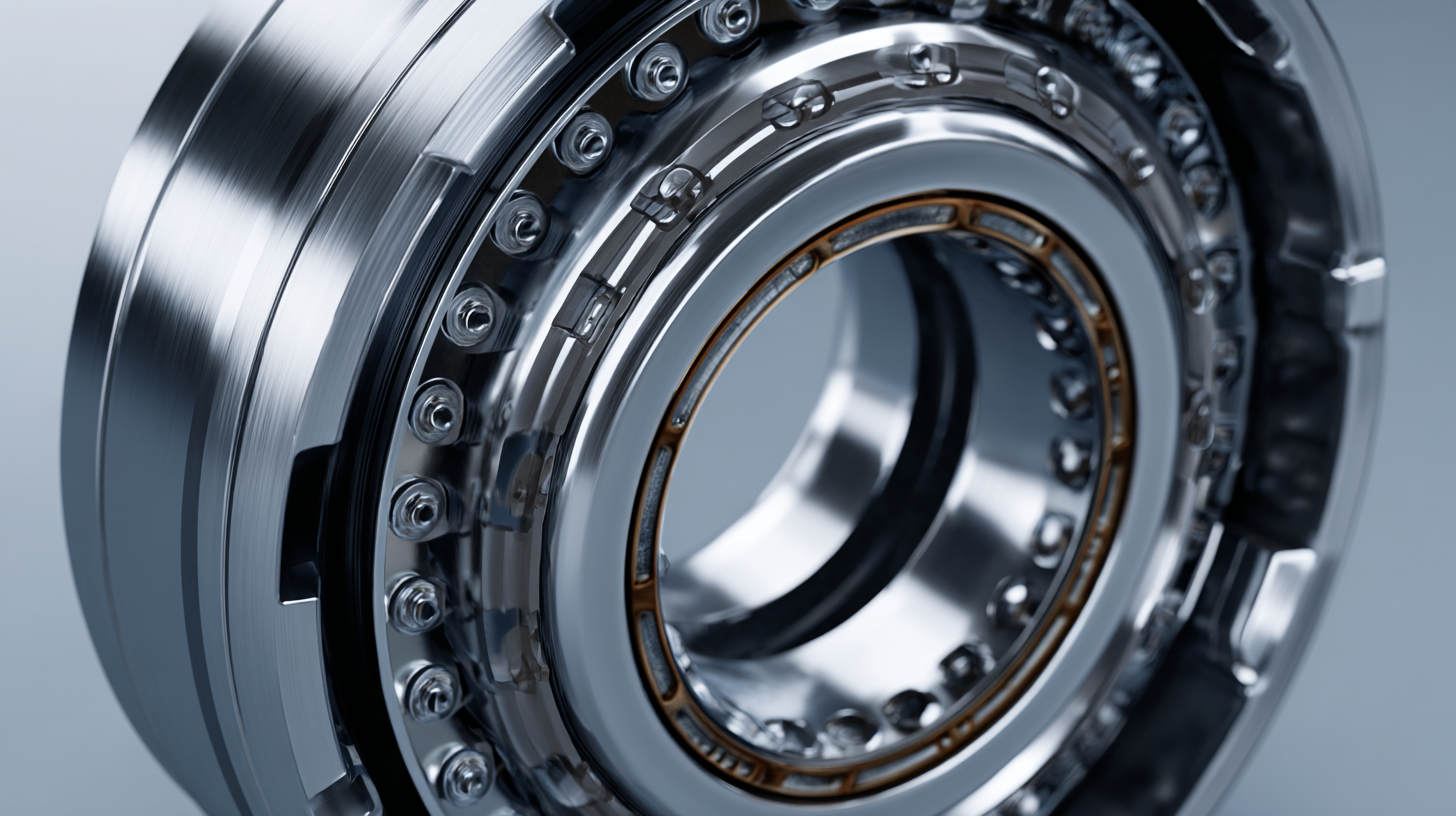

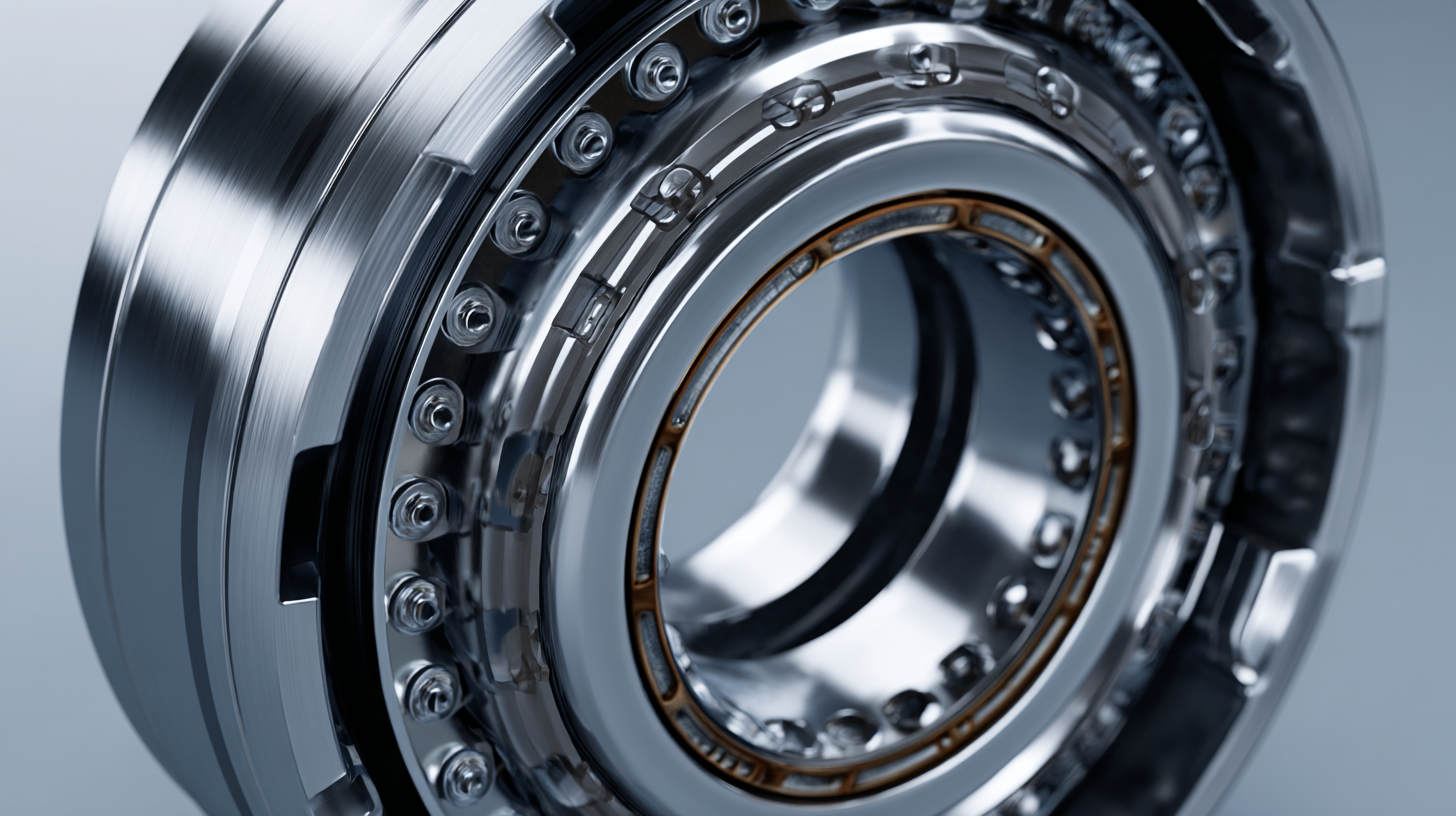

What Are Sealed Thrust Bearings and How Do They Work?

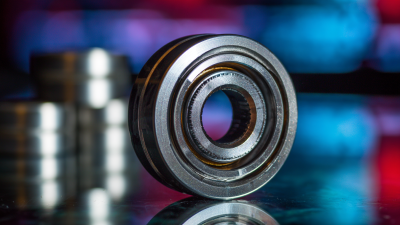

Sealed thrust bearings are essential components in various mechanical systems, designed to manage axial loads while minimizing friction and wear. These specialized bearings incorporate sealing elements that help contain lubricants and prevent contaminants from entering the bearing assembly. This not only prolongs the lifespan of the bearing but also enhances the overall efficiency of the machinery in which they are utilized. Typically found in applications ranging from automotive transmissions to industrial machinery, sealed thrust bearings play a crucial role in maintaining optimal performance.

When selecting sealed thrust bearings, consider the operating environment. Certain applications may expose bearings to extreme temperatures or harsh chemicals, necessitating specific materials or sealing options. Always consult the manufacturer’s specifications to ensure compatibility with your system.

Tip: Regular maintenance is key to maximizing the durability of sealed thrust bearings. Employ a routine inspection schedule to monitor for signs of wear or contamination. Catching potential issues early can save significant costs down the line and promote smooth operation. Additionally, using appropriate lubricants that match the bearing’s requirements can dramatically enhance their performance and lifespan.

Key Advantages of Using Sealed Thrust Bearings in Various Industries

Sealed thrust bearings are increasingly recognized for their significant advantages across various industries, particularly in applications requiring high load capacity and reliability. According to a report by the International Journal of Mechanical Engineering and Technology, sealed thrust bearings can reduce friction losses by up to 30% compared to traditional open bearings. This friction reduction not only enhances operational efficiency but also extends the lifespan of machinery, resulting in lower maintenance costs and reduced downtime.

In the automotive sector, where performance and safety are paramount, sealed thrust bearings are indispensable. A study from the Society of Automotive Engineers highlights that these bearings can support axial loads more effectively, allowing for improved handling and control. Additionally, their ability to retain lubrication in harsh environments protects components from wear, which is crucial in high-performance vehicles. Industries such as aerospace and manufacturing also benefit from the use of sealed thrust bearings. Their design prevents contamination, ensuring operational integrity even in challenging conditions, which contributes to enhanced performance metrics and reliability in high-stakes applications.

Common Applications of Sealed Thrust Bearings: A Comprehensive Overview

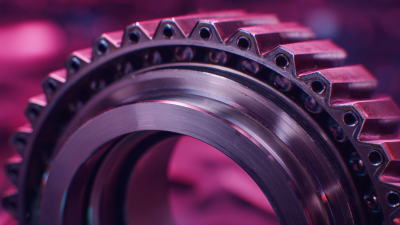

Sealed thrust bearings play a crucial role in various industrial applications by providing support and reducing friction in axial load conditions. They are commonly used in automotive industries, where they enable smooth operation in transmissions and differential systems. According to a report by the Global Bearing Market, the automotive sector accounts for approximately 40% of the total bearing market, highlighting the significant demand for sealed thrust bearings due to their reliability and performance under high-stress environments.

Moreover, sealed thrust bearings are essential in the manufacturing of heavy machinery, such as turbines and conveyor systems. These bearings ensure optimal operation by preventing contamination from dust and moisture, which can lead to premature wear. The Industrial Equipment and Components Market Report indicates that the demand for sealed bearings is expected to grow at a CAGR of 5.2% over the next five years, driven by the increasing need for efficient heavy machinery in various sectors, including construction and mining. This emphasizes the importance of this component in enhancing operational efficiency and longevity of complex machinery.

Ultimate Guide to Understanding Sealed Thrust Bearings and Their Applications

| Application Area |

Industry |

Load Capacity (kN) |

Operating Temperature (°C) |

Common Material |

| Automotive Engineering |

Automotive |

30 |

-30 to 120 |

Steel |

| Heavy Machinery |

Construction |

50 |

-20 to 100 |

Bronze |

| Marine Applications |

Marine |

70 |

-15 to 80 |

Stainless Steel |

| Aerospace Components |

Aerospace |

25 |

-40 to 150 |

Titanium |

| Industrial Gearboxes |

Manufacturing |

60 |

-10 to 95 |

Carbon Steel |

Tips for Selecting the Right Sealed Thrust Bearing for Your Project

When selecting the right sealed thrust bearing for your project, it’s crucial to consider several key factors to ensure optimal performance. First, evaluate the load capacity of the bearing. Understand the amount of axial load the bearing will encounter in your application, as this will influence the lifespan and reliability of the bearing. Look for specifications that align with your project's requirements to avoid premature failure.

Another important tip is to pay attention to the operating conditions, such as temperature and environment. Sealed thrust bearings come with various sealing options that cater to specific conditions, protecting the internal components from contaminants. Choose a bearing that features seals compatible with the environment it operates in, ensuring durability and reduced maintenance needs.

Lastly, consider the lubrication method. Some sealed thrust bearings come pre-lubricated, while others may require additional lubrication during installation. Assessing the ease of lubrication and maintenance can greatly impact the long-term efficiency of your project. By focusing on load capacity, operating conditions, and lubrication options, you can select the ideal sealed thrust bearing that meets your specific needs effectively.

Maintenance Best Practices for Ensuring Longevity of Sealed Thrust Bearings

Sealed thrust bearings are crucial components in various machinery, requiring proper maintenance to ensure their longevity and performance. Regular inspection is vital; it helps identify potential issues before they escalate. Look for signs of wear, such as unusual noises or vibrations, which could indicate that the bearing needs attention. Keeping the surrounding area clean and free of debris will also help maintain optimal operating conditions.

One effective tip for extending the life of sealed thrust bearings is to ensure that they are lubricated correctly. Use the recommended lubricant and establish a regular schedule for lubrication, as it helps reduce friction and heat buildup. Additionally, check the seals regularly for any signs of damage or wear, as compromised seals can lead to contamination and premature failure of the bearings.

Lastly, maintaining proper alignment during installation is critical. Misalignment can cause uneven load distribution, leading to accelerated wear. Use precision tools to verify alignment during setup and periodically check it during operation. By adhering to these best practices, you can significantly enhance the performance and lifespan of sealed thrust bearings in your equipment.