5 Key Benefits of Tapered Roller Bearings: Boost Efficiency by 30% in Your Machinery!

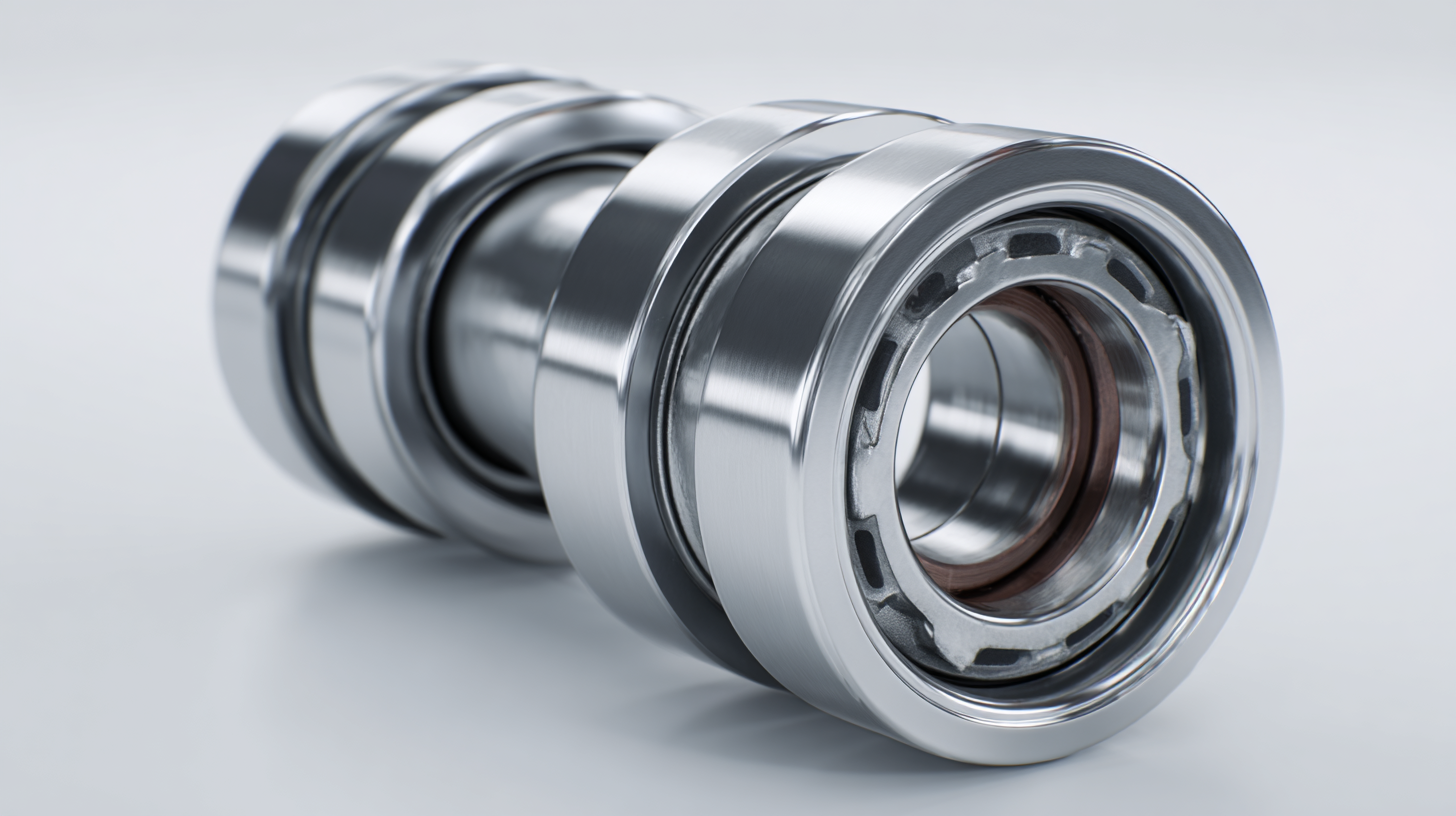

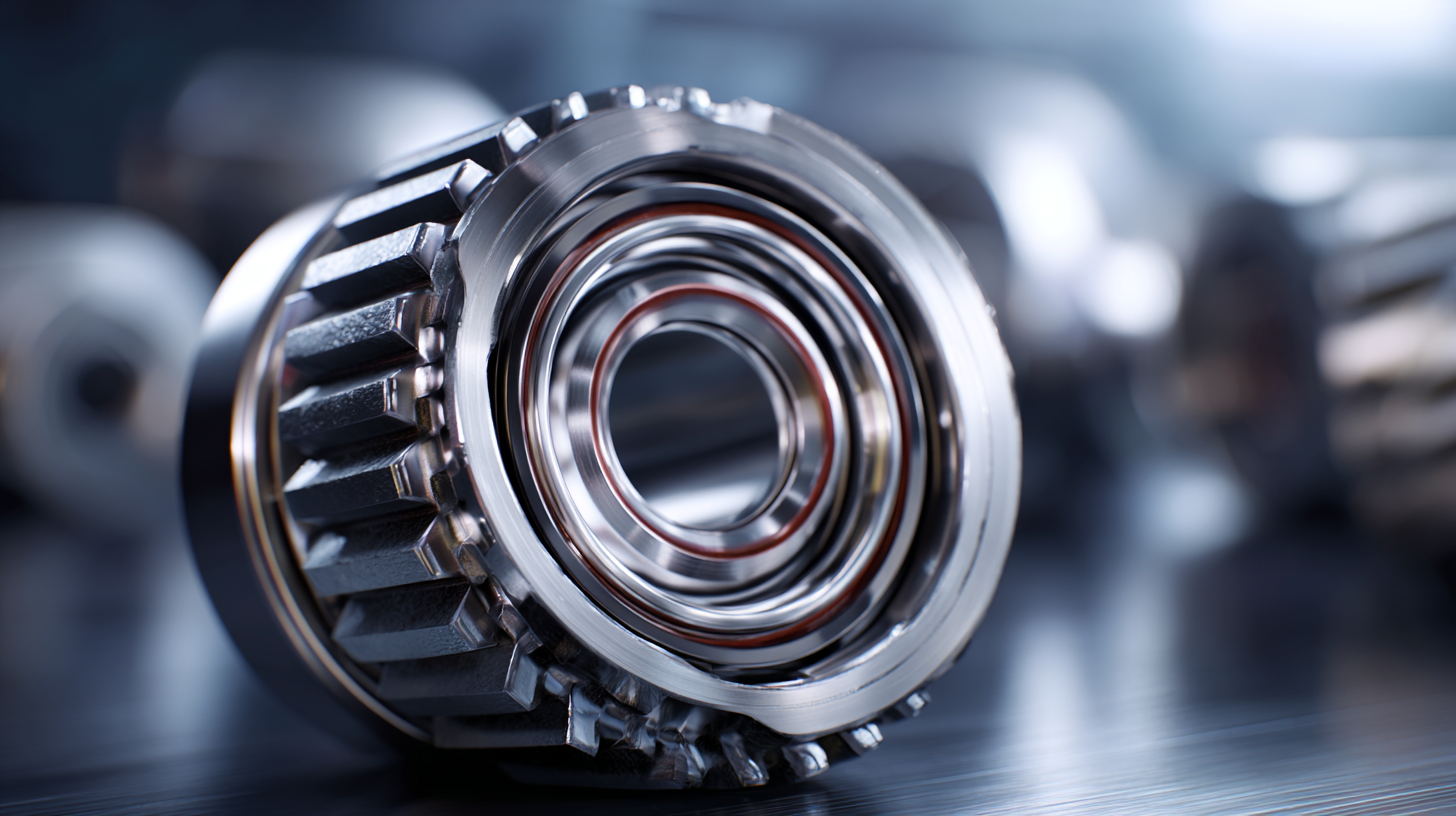

In the world of industrial machinery, the efficiency of components plays a crucial role in overall performance and reliability. One such component that significantly impacts machinery efficiency is the

tapered roller bearing. Designed to accommodate both radial and axial loads, tapered roller bearings excel in applications requiring high load capacity and precision. Their unique design allows for optimal contact between the rollers and raceways, reducing friction and wear, ultimately leading to

enhanced performance. By utilizing tapered roller bearings, manufacturers can experience efficiency boosts of up to

30%, making them an essential choice for modern machinery. In this article, we will explore the five key benefits of tapered roller bearings and how they can transform your operations, ensuring your machinery runs smoother, lasts longer, and operates at peak

efficiency.

Advantages of Tapered Roller Bearings: Enhancing Load Distribution by 20%

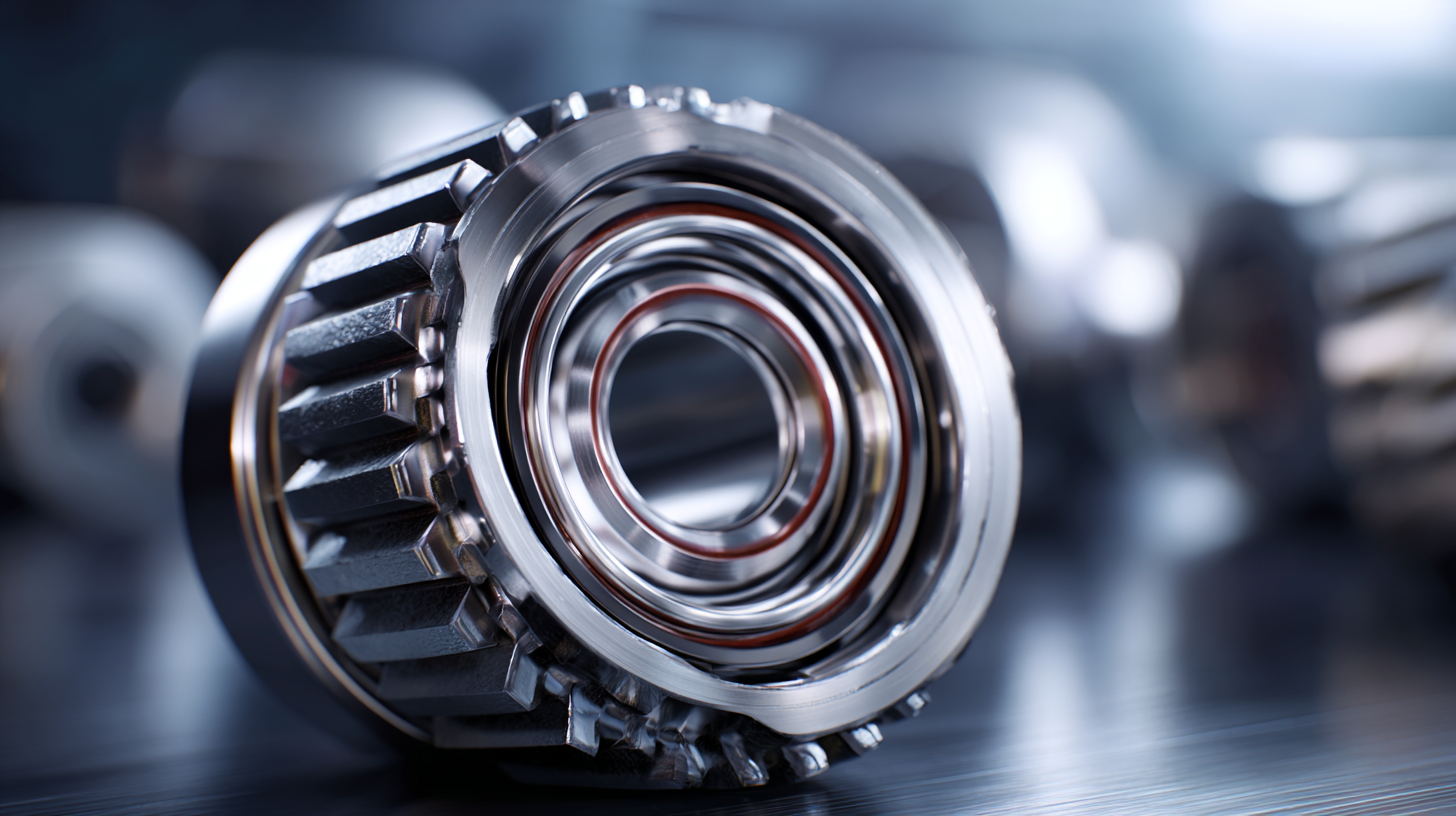

Tapered roller bearings offer significant advantages in load distribution, enhancing machinery performance and longevity. Their unique design allows for the handling of both radial and axial loads, distributing stress more evenly across the bearing surface. This improved load distribution can lead to a 20% increase in efficiency, as it minimizes localized wear and tear, thereby extending the lifespan of both the bearings and the associated machinery.

Additionally, the tapered shape of these bearings enables them to accommodate varying loads, making them ideal for applications that experience fluctuating forces. By effectively managing the distribution of weight, tapered roller bearings reduce the risk of failure and ensure smoother operation. This not only boosts performance but also lowers maintenance costs, as machinery downtime due to bearing issues is significantly decreased. The result is a more reliable and efficient system that meets the demands of modern industrial applications.

Reducing Friction Loss: Achieving Up to 25% Improved Energy Efficiency

Tapered roller bearings play a crucial role in enhancing the overall efficiency of machinery by significantly reducing friction loss. When these bearings are integrated into mechanical systems, they allow for smoother rotational movement, minimizing the energy wasted as heat. This reduction in friction not only prolongs the life of the machinery but also enables it to operate at higher speeds with less energy consumption, translating into tangible cost savings for manufacturers.

Moreover, the design of tapered roller bearings contributes to optimal load distribution, which further improves energy efficiency. By allowing for better alignment and contact between the roller and raceway, these bearings effectively handle both radial and axial loads. This capability enables machinery to work more seamlessly under various operating conditions, achieving up to 25% improved energy efficiency. As businesses strive to reduce operational expenses and environmental impact, adopting tapered roller bearings is a strategic move towards creating more efficient and sustainable machinery solutions.

Extending Machinery Lifespan: Tapered Roller Bearings Reduce Wear by 30%

Tapered roller bearings are instrumental in enhancing the longevity of machinery. By minimizing contact friction and distributing loads more effectively, these bearings significantly reduce wear and tear, extending the operational lifespan of equipment. According to a study from the American Bearing Manufacturers Association (ABMA), proper implementation of tapered roller bearings can lead to a reduction in wear by up to 30%, allowing machinery to perform efficiently over longer periods without the need for frequent replacements.

In high-demand industries, such as automotive and manufacturing, the benefits of tapered roller bearings become even more pronounced. Research from the International Organization for Standardization (ISO) indicates that machinery downtime due to bearing failures can cost companies over $200,000 per incident. By employing tapered roller bearings, businesses can enhance reliability and reduce maintenance costs, effectively optimizing their operations. This reduced wear translates not only to cost savings but also contributes to improved overall efficiency, enabling machinery to maintain peak performance in challenging environments.

Increasing Precision in Machinery: Tapered Roller Bearings Ensure Up to 15% Better Alignment

Tapered roller bearings are increasingly recognized for their ability to enhance alignment precision in machinery, achieving up to 15% better alignment compared to traditional bearings. This precision is crucial in high-load applications where the accurate distribution of weight is essential. By minimizing misalignment, these bearings not only reduce wear on machinery but also increase operational efficiency, leading to less downtime and maintenance.

Tips for selecting tapered roller bearings include evaluating the load capacity and operating conditions of your machinery. Ensure that you choose a bearing type that matches your specific application to maximize performance. Regularly monitor the condition of bearings through maintenance checks—keeping them clean and correctly lubricated can further enhance their alignment capabilities and overall lifespan.

Additionally, consider the installation process carefully. Using a bearing installation tool kit can ensure proper alignment and reduce the risk of damaging the bearings during setup. This proactive approach to bearing selection and maintenance can make a significant difference in productivity and efficiency in any mechanical system.

5 Key Benefits of Tapered Roller Bearings

Tapered roller bearings enhance efficiency in machinery by 30% while improving alignment precision by 15%. The chart illustrates the key benefits of these bearings, showcasing efficiency, load capacity, durability, and heat resistance.

Cost Savings Through Efficiency: How Tapered Roller Bearings Can Cut Operating Costs by 10%

Tapered roller bearings are essential components that significantly enhance the efficiency of machinery. By utilizing these bearings, businesses can experience notable cost savings through improved operational efficiency. Tapered roller bearings are designed to handle both radial and axial loads, allowing for smoother performance and reduced friction. This leads to lower energy consumption during operation, translating directly into savings on energy bills.

Additionally, the durability and reliability of tapered roller bearings contribute to decreased maintenance costs. Their unique design minimizes wear and tear, extending the lifespan of both the bearings and the machinery they support. This reduction in maintenance frequency not only saves on repair costs but also increases overall productivity, as machinery downtime can be costly. By investing in tapered roller bearings, companies can cut operating costs by as much as 10%, fostering a more sustainable and economically sound business model.