Exploring Real World Applications of the Best Roller Bearings in Various Industries

In today's fast-paced industrial landscape, the significance of high-quality roller bearings cannot be overstated. As the backbone of countless machinery and equipment, these vital components enhance operational efficiency and reliability across various sectors. This blog aims to delve into the real-world applications of the best roller bearings, highlighting how meticulously crafted products from China are leading the global market. With a focus on quality, these bearings not only meet stringent international standards but also cater to the diverse needs of industries ranging from automotive to aerospace. By exploring their performance and impact, we will uncover why roller bearings are indispensable in driving advancements, promoting sustainability, and ensuring smooth operations worldwide. Join us as we embark on this insightful journey to appreciate the critical role of roller bearings in shaping the future of industrial performance.

Real World Applications of Roller Bearings in Manufacturing Industries

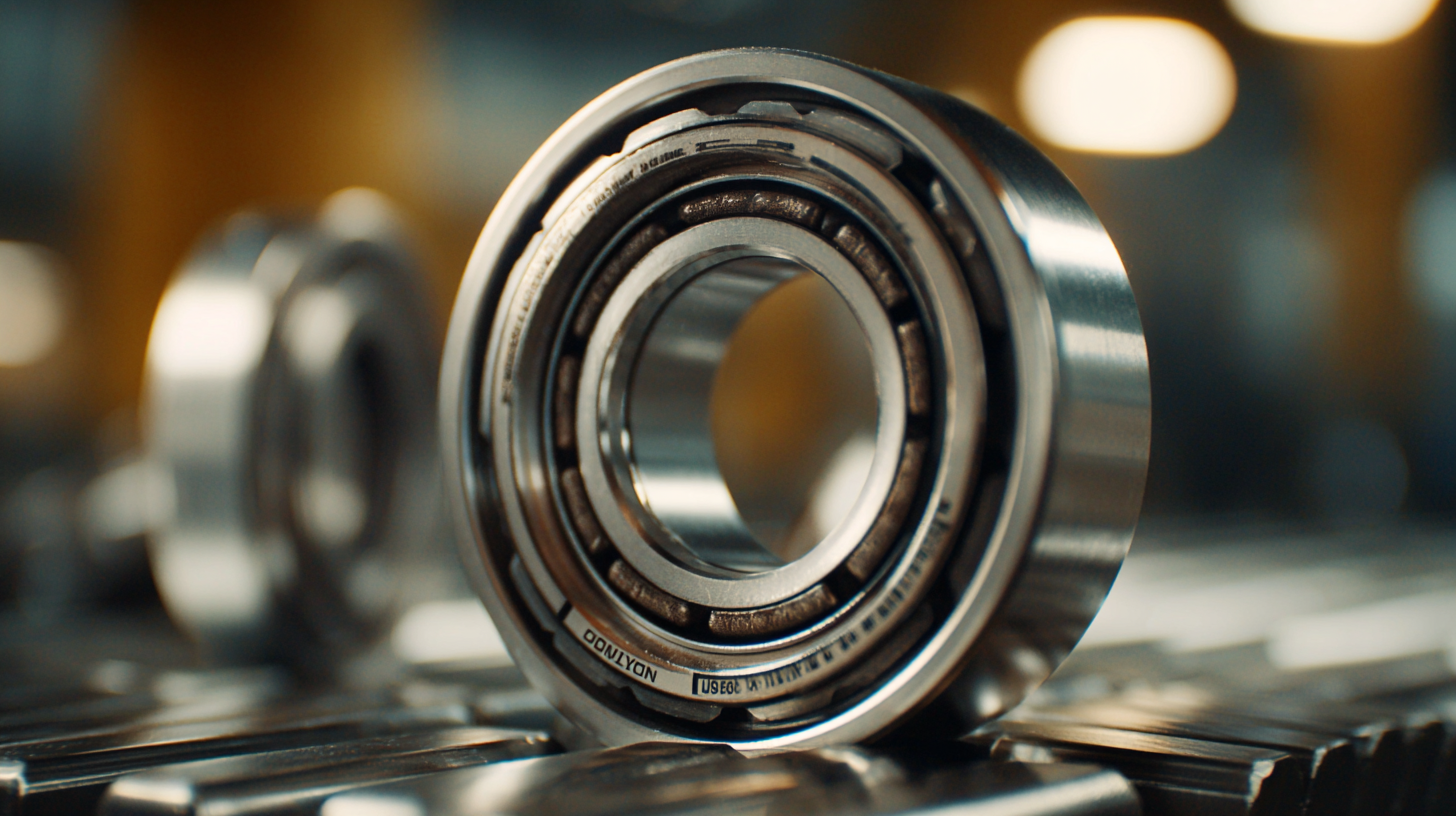

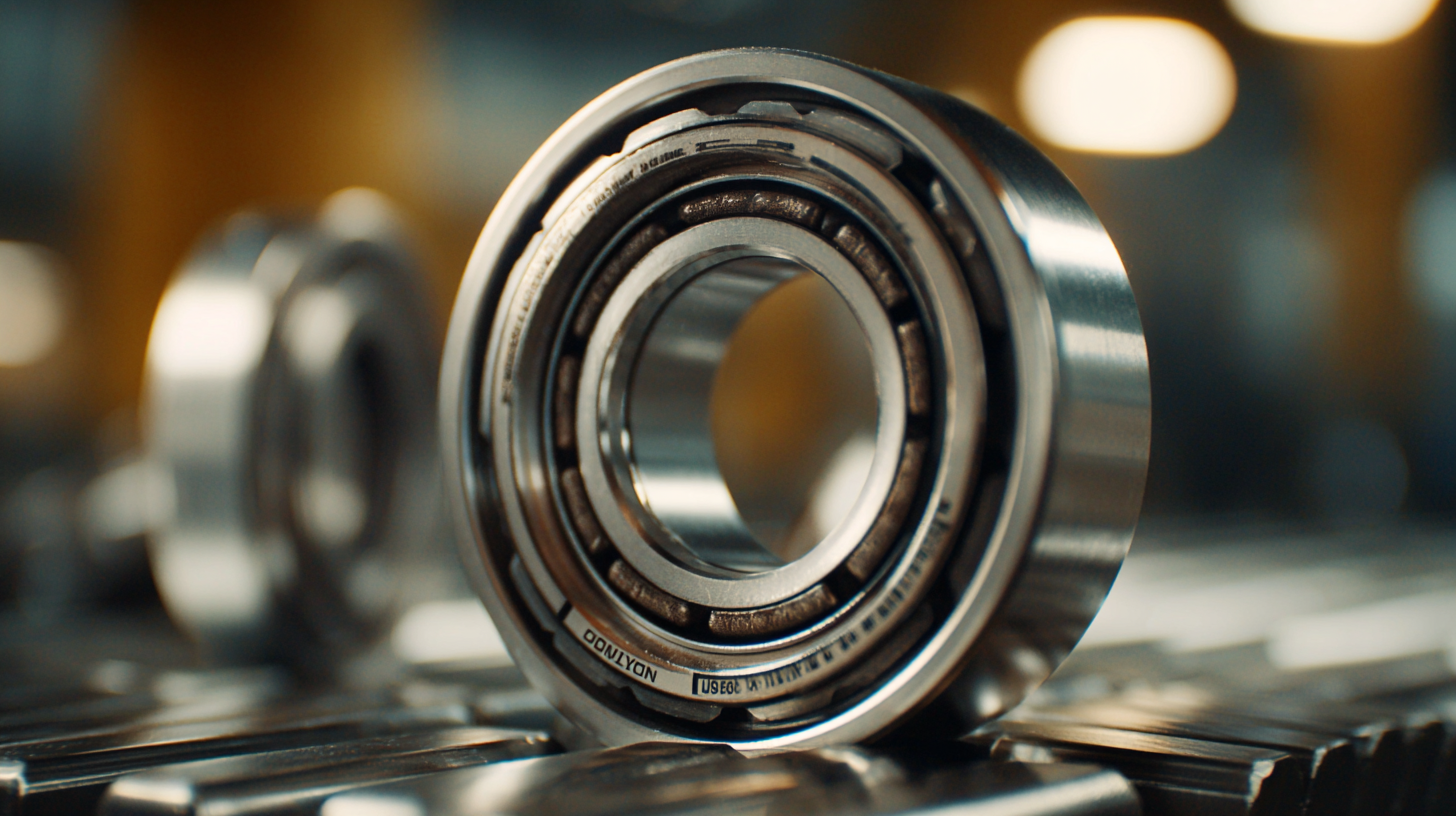

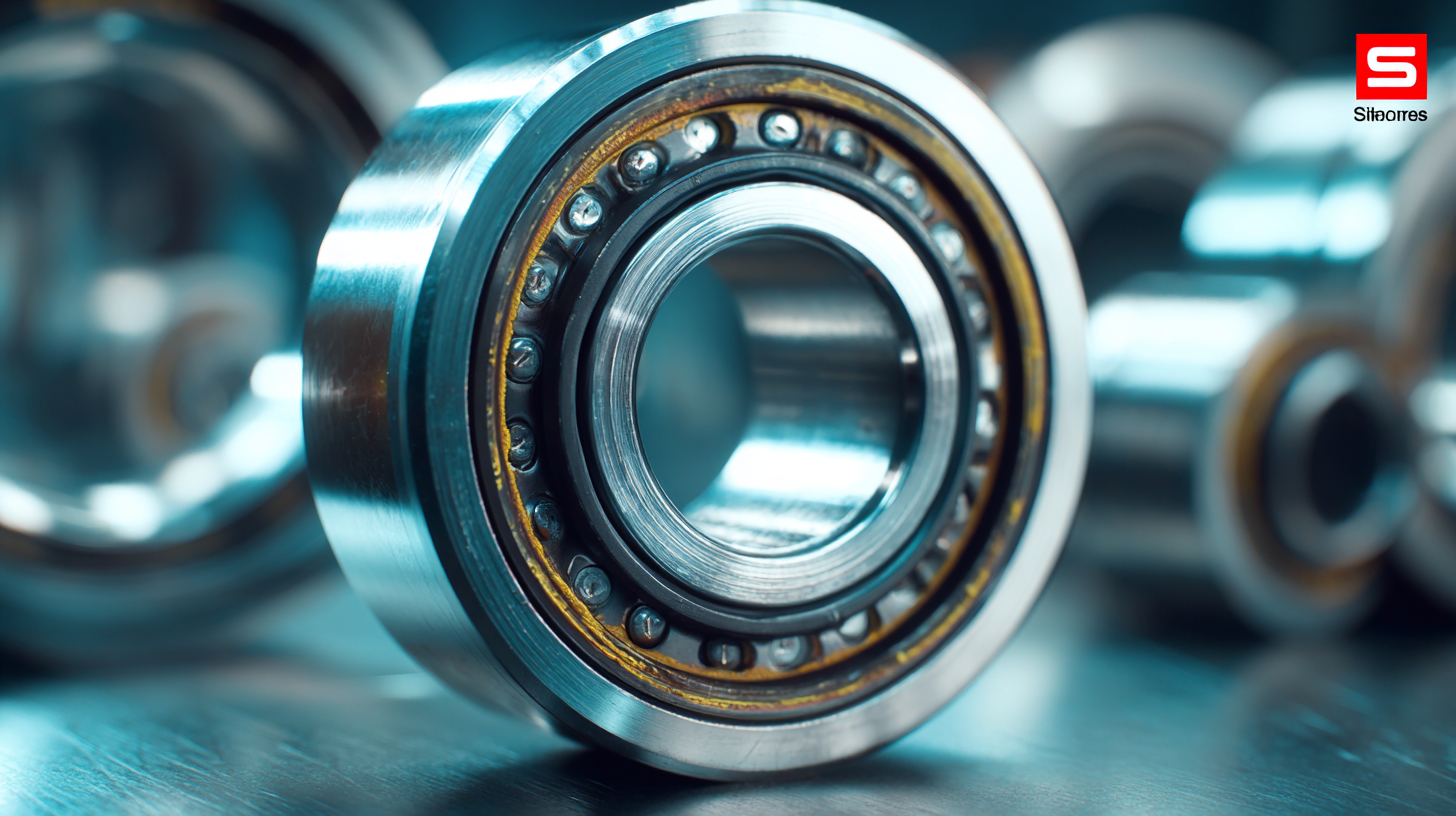

Roller bearings play a crucial role in the manufacturing industries, significantly enhancing efficiency and productivity. According to a report by MarketsandMarkets, the global roller bearings market was valued at approximately $25 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2028. A primary application of roller bearings lies in machinery that requires high-speed operations, such as conveyor systems and rotary actuators, where reduced friction translates to increased reliability and lower maintenance costs.

In the automotive sector, roller bearings are pivotal in ensuring optimal performance and longevity of components like engines and transmissions. The International Journal of Advanced Manufacturing Technology estimates that using high-quality roller bearings can improve fuel efficiency by up to 3%. Additionally, in the aerospace industry, bearings are subjected to extreme conditions; thus, the adoption of advanced ceramic roller bearings helps withstand high temperatures and stresses, contributing to better aircraft performance and safety. The integration of roller bearings in these industries exemplifies their vital contribution to enhancing operational efficiency and cost savings.

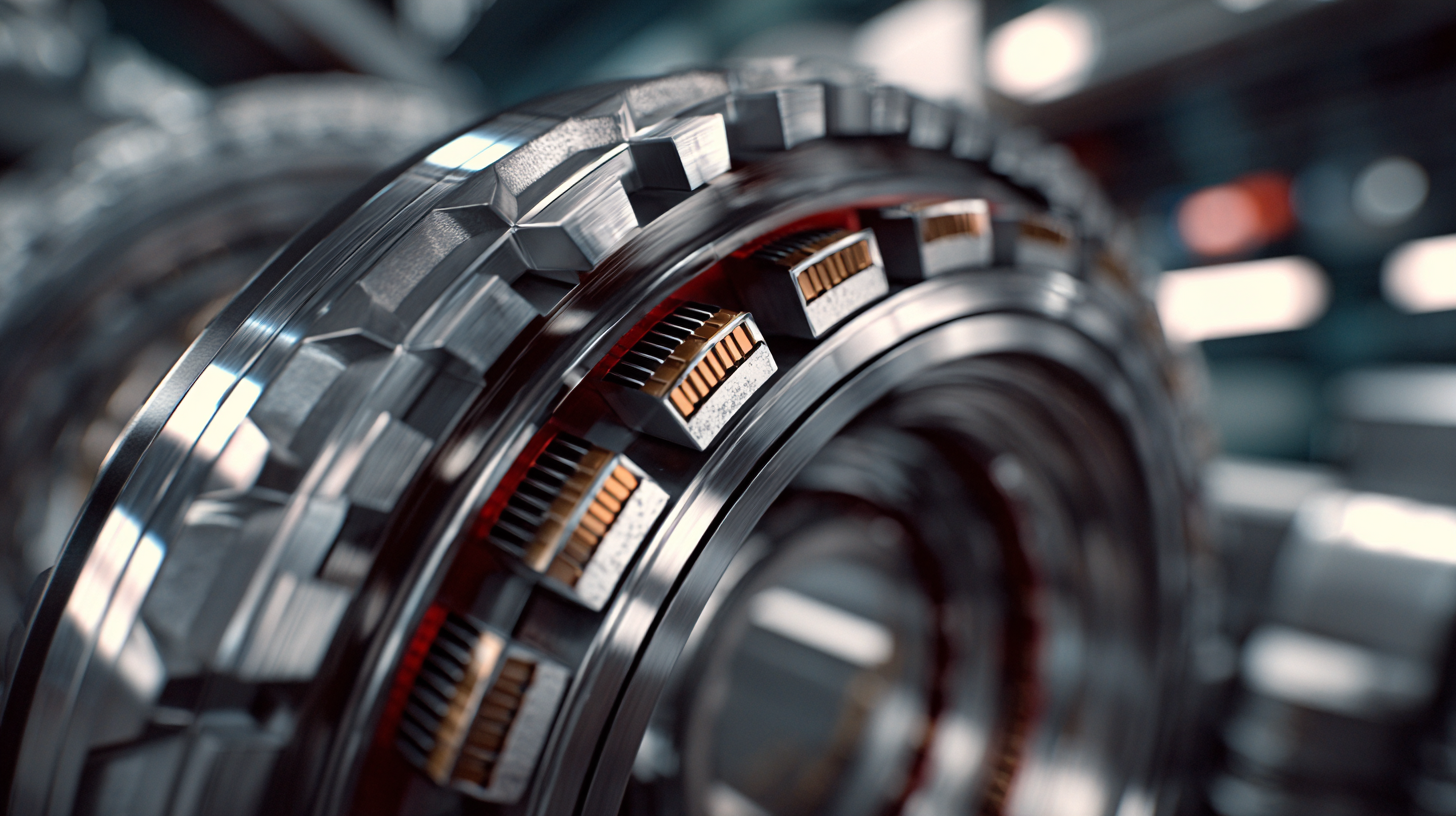

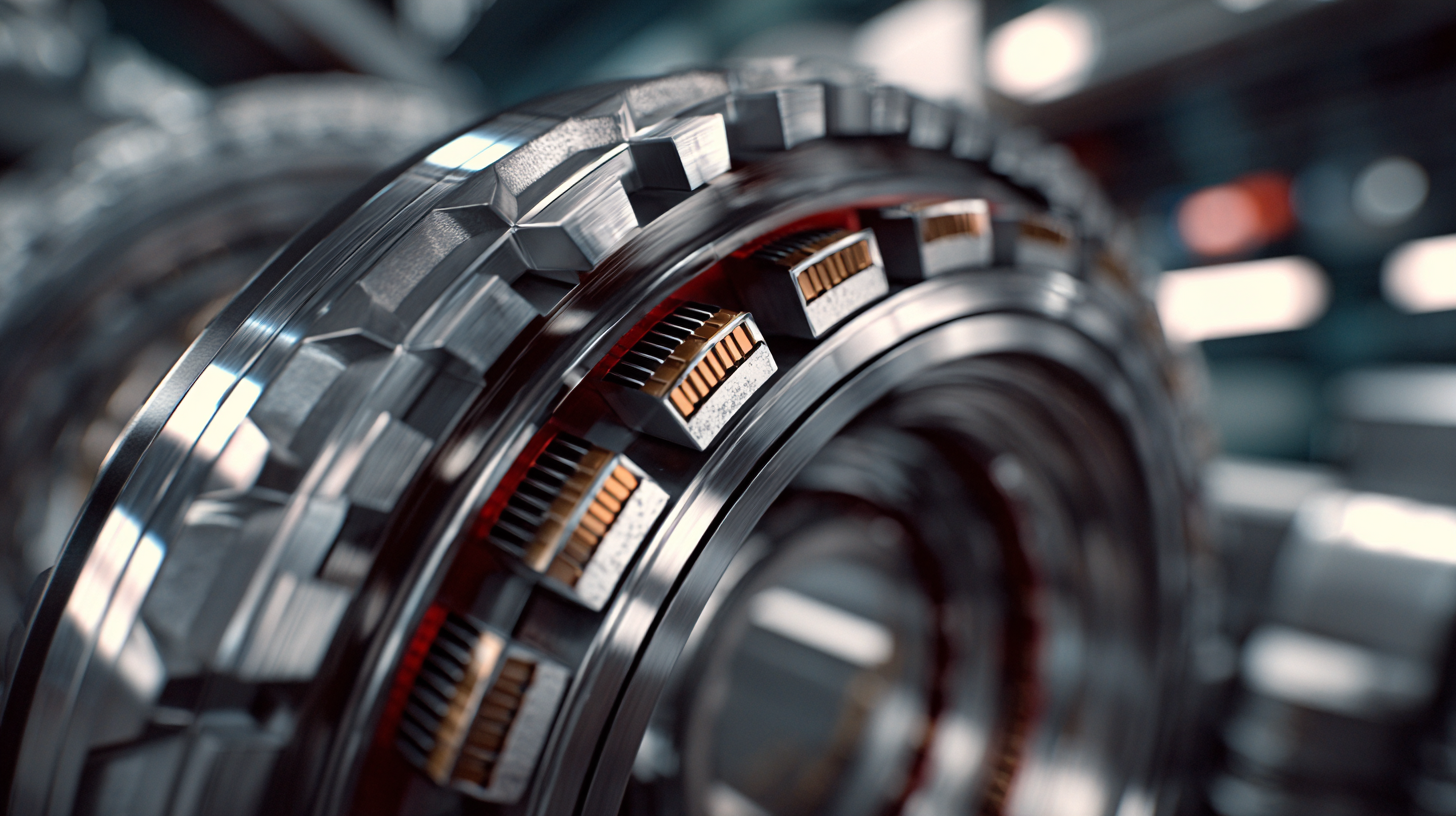

The Role of Roller Bearings in Automotive Engineering and Performance

In automotive engineering, roller bearings serve as crucial components that significantly enhance vehicle performance and reliability. These precision-engineered elements reduce friction between moving parts, enabling smoother operation of critical systems such as the drivetrain, wheel assemblies, and engine components. By allowing for a more efficient transfer of power and reduction of heat generation, high-quality roller bearings contribute to improved fuel efficiency and extended vehicle lifespan.

In automotive engineering, roller bearings serve as crucial components that significantly enhance vehicle performance and reliability. These precision-engineered elements reduce friction between moving parts, enabling smoother operation of critical systems such as the drivetrain, wheel assemblies, and engine components. By allowing for a more efficient transfer of power and reduction of heat generation, high-quality roller bearings contribute to improved fuel efficiency and extended vehicle lifespan.

Moreover, the automotive industry continuously seeks innovations in roller bearing technology to meet the demands of modern vehicles. With the rise of electric powertrains and advanced suspension systems, the design and materials used in roller bearings have evolved, allowing for higher load capacities and better performance under extreme conditions. This evolution not only boosts overall vehicle performance but also supports the sustainability goals of manufacturers by enhancing energy efficiency and reducing wear and tear on parts, leading to lower maintenance costs over time. Thus, roller bearings have become indispensable in realizing the potential of next-generation automotive engineering.

Innovative Uses of Roller Bearings in Aerospace Technology

Roller bearings play a critical role in the aerospace industry, where precision and reliability are paramount. These components are essential for minimizing friction and wear in aircraft engines, landing gear, and control surfaces. The unique ability of roller bearings to tolerate heavy loads while providing smooth performance allows aerospace engineers to design more efficient and durable systems. By incorporating advanced materials and innovative designs, modern roller bearings have significantly enhanced the performance of crucial aviation components, ensuring safety and longevity.

One of the most innovative applications of roller bearings in aerospace technology includes their use in turbine engines. As these engines operate at extreme temperatures and speeds, specialized roller bearings are engineered to maintain stability and reduce drag. Moreover, the integration of high-strength materials, such as ceramic and specialized alloys, has improved the weight-to-strength ratio of these bearings, contributing to overall fuel efficiency. Additionally, with the rise of electric and hybrid aircraft, roller bearings are being adapted to meet the evolving demands of these new propulsion systems, showcasing their versatility and importance in the future of aviation.

Innovative Uses of Roller Bearings in Aerospace Technology

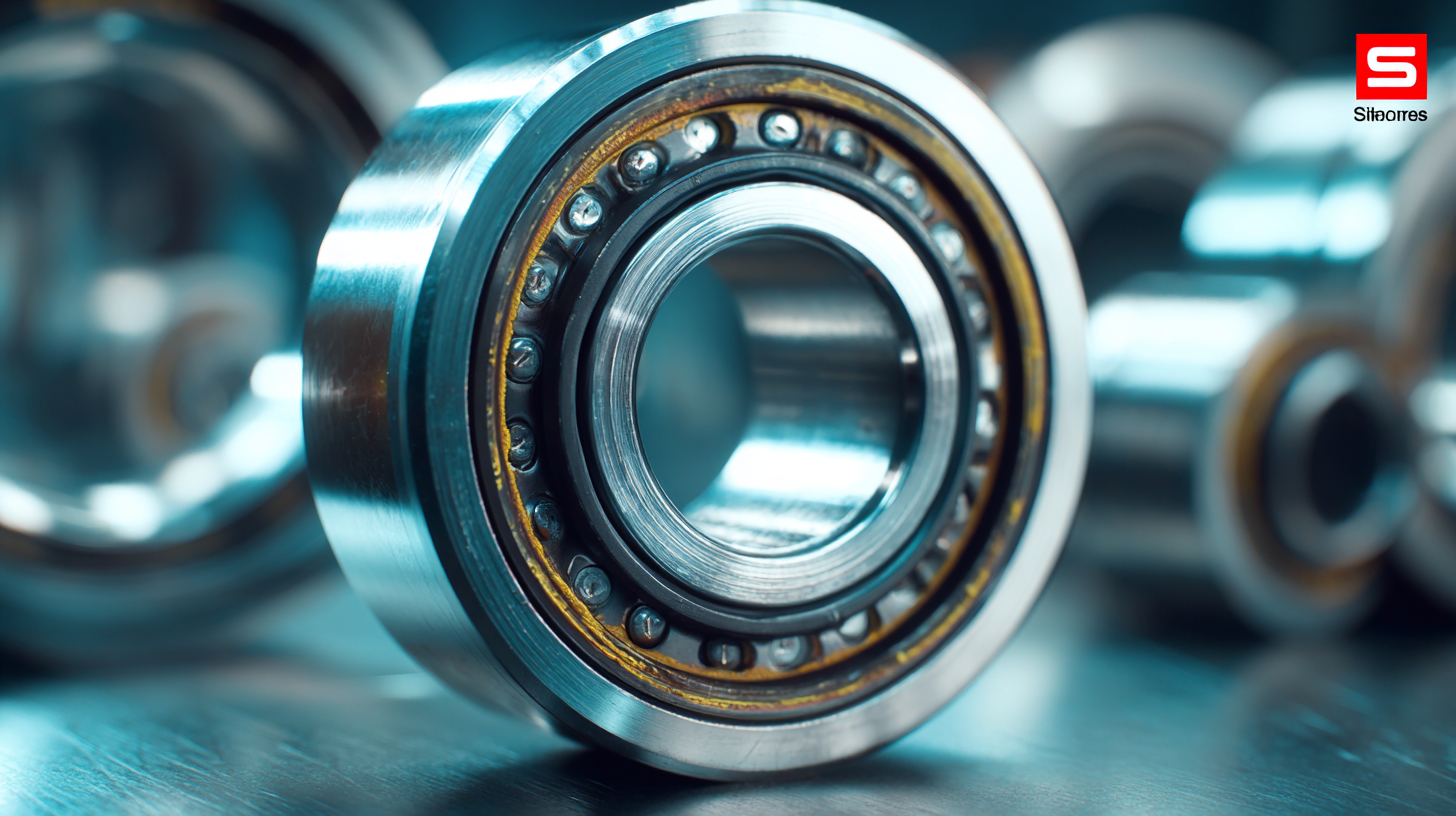

Enhancing Efficiency: Roller Bearings in Renewable Energy Solutions

Roller bearings play a crucial role in enhancing the efficiency of renewable energy solutions. In wind turbines, for instance, high-quality roller bearings reduce friction between moving parts, allowing for smoother operation and less energy loss. This efficiency is vital as it directly impacts the overall performance and lifespan of the turbines, ultimately leading to increased power generation and reduced maintenance costs.

Roller bearings play a crucial role in enhancing the efficiency of renewable energy solutions. In wind turbines, for instance, high-quality roller bearings reduce friction between moving parts, allowing for smoother operation and less energy loss. This efficiency is vital as it directly impacts the overall performance and lifespan of the turbines, ultimately leading to increased power generation and reduced maintenance costs.

When implementing roller bearings in renewable energy systems, it’s essential to choose the right type for specific applications. Tip: Always consider environmental factors, such as humidity and temperature variations, as these can affect the performance and durability of the bearings over time. Investing in bearings that are designed to withstand these conditions can provide long-term benefits to efficiency and reliability.

Moreover, the selection of advanced materials for roller bearings, such as ceramics or special alloys, can lead to significant improvements in their performance. Tip: Regularly monitor the condition of roller bearings to ensure they are functioning optimally. Employing predictive maintenance strategies can help detect potential issues early, preventing costly downtime and ensuring that renewable energy systems operate at peak efficiency.

Challenges and Solutions in Roller Bearing Utilization Across Different Sectors

Roller bearings play a crucial role in various industries, yet their utilization often comes with challenges that must be addressed to maximize efficiency. One of the primary issues faced is contamination. In industries such as construction and mining, dust and debris can rapidly degrade bearing performance. According to a 2022 report by the Machinery Lubrication Association, around 40% of bearing failures are attributed to contamination. Implementing effective seals and filtration systems can significantly enhance bearing life, making these solutions invaluable.

Another challenge is the thermal management of roller bearings, especially in high-speed applications like automotive and aerospace. Elevated temperatures can lead to lubrication breakdown, increasing friction and wear. A study published in the Journal of Mechanical Engineering indicated that proper temperature monitoring can reduce bearing-related failures by up to 30%. Investing in advanced monitoring tools allows for real-time data collection, helping industries promptly address potential overheating issues.

**Tips**: Regularly check lubrication levels and quality to prevent overheating and wear. Additionally, consider integrating enhanced sealing technology for environments with high contamination risk. Finally, maintain a robust maintenance schedule to ensure bearings are inspected and serviced routinely, reducing the overall risk of failure.

Exploring Real World Applications of the Best Roller Bearings in Various Industries - Challenges and Solutions in Roller Bearing Utilization Across Different Sectors

| Industry |

Application |

Challenges |

Solutions |

| Automotive |

Wheel Hubs |

High load and temperature variations |

Advanced materials and lubrication techniques |

| Aerospace |

Engine Components |

Weight constraints and precision |

Use of titanium and composite materials |

| Heavy Machinery |

Excavators |

Extreme operating conditions |

Sealed bearings and regular maintenance |

| Textile |

Spinning Machines |

Dust and lint accumulation |

Installing filter systems and regular cleaning |

| Food Processing |

Conveyor Systems |

Sanitation and contamination risks |

Use of stainless steel and FDA-compliant lubricants |

In automotive engineering, roller bearings serve as crucial components that significantly enhance vehicle performance and reliability. These precision-engineered elements reduce friction between moving parts, enabling smoother operation of critical systems such as the drivetrain, wheel assemblies, and engine components. By allowing for a more efficient transfer of power and reduction of heat generation, high-quality roller bearings contribute to improved fuel efficiency and extended vehicle lifespan.

In automotive engineering, roller bearings serve as crucial components that significantly enhance vehicle performance and reliability. These precision-engineered elements reduce friction between moving parts, enabling smoother operation of critical systems such as the drivetrain, wheel assemblies, and engine components. By allowing for a more efficient transfer of power and reduction of heat generation, high-quality roller bearings contribute to improved fuel efficiency and extended vehicle lifespan.

Roller bearings play a crucial role in enhancing the efficiency of renewable energy solutions. In wind turbines, for instance, high-quality roller bearings reduce friction between moving parts, allowing for smoother operation and less energy loss. This efficiency is vital as it directly impacts the overall performance and lifespan of the turbines, ultimately leading to increased power generation and reduced maintenance costs.

Roller bearings play a crucial role in enhancing the efficiency of renewable energy solutions. In wind turbines, for instance, high-quality roller bearings reduce friction between moving parts, allowing for smoother operation and less energy loss. This efficiency is vital as it directly impacts the overall performance and lifespan of the turbines, ultimately leading to increased power generation and reduced maintenance costs.