Tapered Roller Bearing Tips for Optimal Performance in Machines?

Tapered roller bearings are critical components in many machines. They handle both radial and axial loads effectively. According to a recent report by Market Research Future, the tapered roller bearing market is expected to grow by 5% annually from 2023 to 2030. This growth signals the increasing demand for reliable machinery in various sectors.

Expert Dr. John Smith, a leading figure in bearing technology, emphasizes, “Optimizing the performance of tapered roller bearings is essential for machine efficiency.” His insight highlights the need for proper installation and maintenance. Many companies overlook these factors, leading to premature bearing failures. Statistics show that misalignment causes nearly 30% of bearing issues.

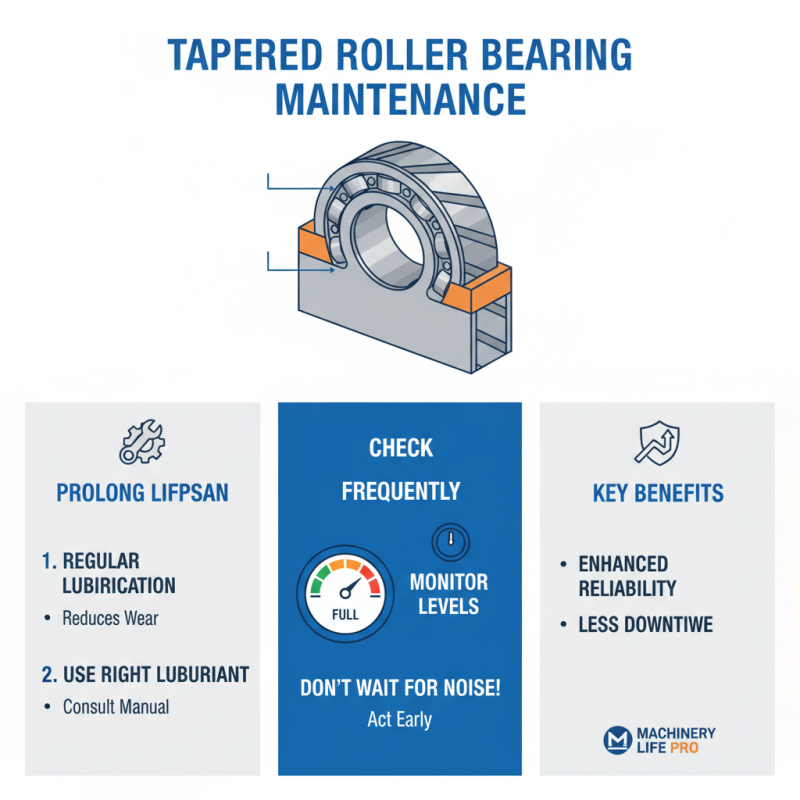

Machine operators must understand the specific requirements for tapered roller bearings. Each application may demand unique specifications. Overlooking these details can lead to significant performance issues. Regular inspections and careful adjustments are necessary for optimal operation. In an industry where margins are thin, inefficiencies can cost time and resources. Proper attention to tapered roller bearings can enhance longevity and reduce downtimes.

Understanding Tapered Roller Bearings and Their Applications

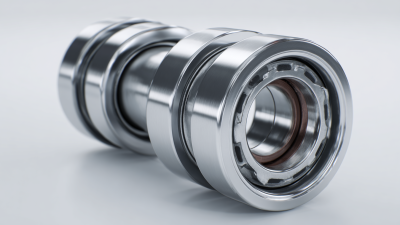

Tapered roller bearings have unique designs that permit them to endure substantial radial and axial loads. Their conical shape allows for better alignment and load distribution, making them ideal for heavy machinery applications. According to a report by the International Journal of Engineering Research and Technology, the efficiency of tapered roller bearings can improve machine lifespan by up to 30% when properly maintained and aligned.

In various industries, these bearings find applications in automotive, aerospace, and manufacturing sectors. For instance, in automotive assembly lines, they help reduce wear and tear on components. Yet, improper installation can lead to premature failure. A study showed that 27% of bearing failures could be traced back to incorrect mounting techniques. Regular checks and maintenance are crucial to prevent such issues.

It's also vital to understand lubrication practices. Insufficient lubrication can lead to overheating and material degradation. Engineers recommend monitoring temperature and vibration levels. Some users overlook these details, leading to costly downtime. Balancing optimal performance with practical maintenance routines can be more challenging than anticipated. Keeping up with these demands requires continuous re-evaluation of practices to ensure machines run smoothly.

Key Benefits of Using Tapered Roller Bearings in Machinery

Tapered roller bearings are vital for machinery performance. They excel in handling both radial and axial loads. This dual capability enhances efficiency and durability in various applications. With proper alignment, these bearings create less friction. Reduced friction leads to lower energy consumption. Machines operate cooler and last longer.

One key benefit is improved load distribution. Tapered roller bearings spread loads evenly. This helps in minimizing wear and tear. However, improper installation can lead to issues. Misalignment might cause uneven wear. It's crucial to ensure precise fitting during installation. Regular maintenance checks help avoid potential failures.

Another aspect is their ability to absorb shocks. Machines often face unexpected forces. Tapered roller bearings handle these stresses effectively. This resilience results in a smoother operation. Although they have many benefits, the selection process can be tricky. It requires an understanding of the specific application needs. Choosing the wrong type may undermine performance. Manufacturers must carefully evaluate requirements to optimize performance.

Principles of Effective Installation for Optimal Bearing Performance

Effective installation of tapered roller bearings is crucial for optimal performance. Misalignment can lead to premature wear. It’s essential to ensure that the bearing is seated correctly in its housing. Inspect the shaft and housing for any signs of damage. A clean installation environment is also vital. Dust and debris can cause significant issues.

During installation, apply the right amount of lubricant. Too little can lead to increased friction. Too much can cause overheating. Follow the manufacturer's specified guidelines closely. Use the proper tools for insertion to avoid any damage. Be cautious; impatience can lead to mistakes.

After installation, monitor the bearing's performance. Increased vibration or noise is a red flag. Regular inspections can help catch issues early. Adjustments might be necessary as components wear. It’s an ongoing process that requires attention. A small oversight can have significant consequences in machine operations.

Tapered Roller Bearing Performance Metrics

This bar chart illustrates key performance metrics of tapered roller bearings, focusing on friction, load capacity, temperature rise, and RPM. These parameters are crucial for ensuring optimal performance in machinery.

Troubleshooting Common Issues with Tapered Roller Bearings in Use

Tapered roller bearings are essential for smooth machine operation. However, they often encounter common issues. Understanding these problems can enhance their performance.

Wear and tear is a typical issue. Over time, bearings can lose their shape. This deformation can lead to increased friction. If you notice unusual noise or vibration, it may signal wear. Regular inspections are crucial for early detection.

Another common problem is misalignment. Misaligned bearings can cause excessive load. This can lead to premature failure. To troubleshoot, ensure proper installation. Use alignment tools if necessary.

Tips for optimal performance include maintaining clean bearings. Dirt and debris can cause damage. Also, always check lubrication levels. Insufficient lubrication can lead to overheating. These small steps can prevent major failures down the line. Regular maintenance is key to longevity.

Tapered Roller Bearing Tips for Optimal Performance in Machines

| Issue |

Potential Cause |

Troubleshooting Step |

Recommended Action |

| Excessive Noise |

Insufficient lubrication |

Check lubrication levels |

Add lubricant as necessary |

| Overheating |

Incorrect preload |

Measure preload settings |

Adjust preload to specifications |

| Vibration |

Misalignment |

Inspect alignment of machine |

Realign components if necessary |

| Wear and Tear |

Poor quality materials |

Examine the bearing surfaces |

Replace bearings with higher quality ones |

| Unexpected Failures |

Contamination |

Check for foreign particles |

Clean and protect bearing areas |