Understanding the Advantages of Needle Thrust Bearings in High Load Applications

In the realm of high load applications, the utilization of needle thrust bearings has garnered significant attention due to their superior performance characteristics and efficiency. According to a report by the International Journal of Engineering Research and Technology, needle thrust bearings are designed to accommodate heavy axial loads while minimizing friction and wear, making them ideal for demanding environments. With a load capacity that can exceed 500,000 N, these bearings provide a robust solution for industries ranging from automotive to aerospace. The recent market analysis by Grand View Research highlights a projected CAGR of 7.5% in the needle thrust bearing segment, driven by the increasing demand for high-performance machinery and equipment. As industries strive for enhanced reliability and reduced downtime, understanding the advantages of needle thrust bearings becomes imperative for engineers and manufacturers seeking to optimize their operations in high load scenarios.

Advantages of Needle Thrust Bearings in High Load Applications

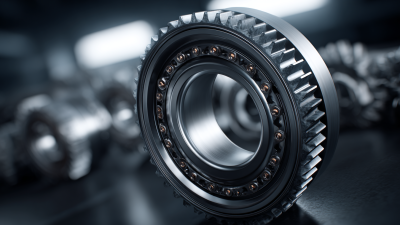

Needle thrust bearings stand out in high load applications due to their ability to efficiently handle significant axial loads while maintaining a compact design. With the global bearings market projected to grow from USD 50.16 billion in 2025 to an impressive USD 97.10 billion by 2030, the demand for specialized solutions such as needle thrust bearings will continue to rise. These bearings are engineered to reduce frictional losses, which translates to enhanced performance and longevity. Their lightweight nature, combined with durability, makes them a key component in various industries, especially where reliability and cost-effectiveness are paramount.

The unique design of needle thrust bearings—characterized by cylindrical rollers that provide a large contact area—contributes to their superior stiffness and displacement characteristics. Experimental and numerical analyses have shown that these properties not only positively influence the reliability and remaining lifespan of the bearings but also enable them to excel under dynamic loading conditions. This is particularly significant in applications such as automotive and industrial machinery, where the combination of high load capacity and low friction can lead to improved efficiency and reduced maintenance costs. As the industry evolves, the continued innovation in needle bearing technologies is likely to propel their use in demanding environments, further solidifying their role as vital components in modern engineering solutions.

Understanding the Advantages of Needle Thrust Bearings in High Load Applications

This chart compares the performance metrics of Needle Thrust Bearings against Standard Bearings in high load applications. The metrics include Load Capacity, Frictional Resistance, Durability, and Cost Efficiency. Needle Thrust Bearings demonstrate superior load capacity and durability, making them a more efficient choice for high load environments.

Key Design Features of Needle Thrust Bearings for Enhanced Performance

Needle thrust bearings are essential components in high load applications, designed to handle significant axial loads while minimizing frictional forces. One of the key design features of these bearings is their cylindrical roller shape, which increases the contact surface area with the raceways. This design allows them to achieve higher load capacities compared to traditional thrust bearings. Additionally, the arrangement of multiple needle rollers in a compact space allows for efficient load distribution, making them ideal for use in applications where space is limited.

Another advantage of needle thrust bearings is their capability to operate at higher speeds while maintaining performance stability. The reduced friction during operation leads to lower heat generation, which enhances the longevity of both the bearings and the machinery they support. Furthermore, specialized materials and surface treatments used in the manufacturing of needle thrust bearings contribute to their durability and reliability, ensuring that they perform effectively under harsh operating conditions. As industries continue to seek more efficient solutions for high-load applications, the demand for needle thrust bearings is expected to rise significantly.

Understanding the Advantages of Needle Thrust Bearings in High Load Applications - Key Design Features of Needle Thrust Bearings for Enhanced Performance

| Feature |

Description |

Advantage |

Application |

| High Load Capacity |

Designed to support heavy axial loads |

Increased durability and reduced risk of failure |

Industrial machinery, automotive applications |

| Compact Design |

Smaller footprint compared to traditional bearings |

Space-saving and lightweight constructions |

Robotics, aerospace applications |

| Low Friction |

Enhanced lubrication features for reduced friction |

Improved efficiency and lower energy consumption |

HVAC systems, conveyor systems |

| High Wear Resistance |

Manufactured from materials resistant to wear |

Longer lifespan and reduced maintenance costs |

Mining equipment, heavy machinery |

| Easy Installation |

User-friendly design for quick setup |

Reduced downtime and labor costs |

General engineering applications, assembly lines |

Comparison of Needle Thrust Bearings to Other Bearing Types in High Loads

Needle thrust bearings are specifically designed to handle high axial loads with minimal friction, making them a superior choice compared to traditional thrust bearings like ball or roller types. According to a recent report from the American Bearing Manufacturers Association (ABMA), needle thrust bearings can bear loads exceeding 40% more than comparable ball bearings, depending on the application. This increased load capacity is primarily due to the larger surface area of the needle-shaped rollers, which allows for better distribution of force, enhancing the performance of machinery under extreme conditions.

Needle thrust bearings are specifically designed to handle high axial loads with minimal friction, making them a superior choice compared to traditional thrust bearings like ball or roller types. According to a recent report from the American Bearing Manufacturers Association (ABMA), needle thrust bearings can bear loads exceeding 40% more than comparable ball bearings, depending on the application. This increased load capacity is primarily due to the larger surface area of the needle-shaped rollers, which allows for better distribution of force, enhancing the performance of machinery under extreme conditions.

When evaluating the performance of needle thrust bearings against other types, it's critical to consider their efficiency in high-load environments. Studies indicate that needle thrust bearings can operate at lower temperatures and with reduced wear, resulting in lower maintenance costs over the lifecycle of industrial equipment. In high-stress applications, such as in automotive transmissions or heavy machinery, the durability and reliability of needle thrust bearings provide a significant advantage. According to recent market analysis, the demand for needle thrust bearings in industrial applications is projected to grow by 6% annually through 2025, reflecting their increasing adoption due to these performance benefits.

Application Areas Where Needle Thrust Bearings Excel in Load Management

Needle thrust bearings have gained significant traction in various high-load applications, particularly in industries that demand superior load management. These bearings excel in scenarios where axial load capacities are essential, such as in automotive and industrial machinery. According to a report by the American Bearing Manufacturers Association, needle thrust bearings can handle loads up to 20% higher than traditional thrust bearings due to their efficient design and minimal friction. This increased load capacity makes them ideal for heavy-duty applications where space is limited, yet high performance is required.

In the realm of construction and heavy equipment, needle thrust bearings are particularly valuable. They are often employed in hydraulic systems, where precise load distribution is crucial for operational efficiency. A study published by the International Journal of Engineering Research and Applications highlighted that the integration of needle thrust bearings in hydraulic pumps led to a 15% increase in energy efficiency due to their ability to maintain high loads with reduced wear over time. This characteristic not only enhances the service life of machinery but also minimizes the downtime for repairs, making it a cost-efficient choice for businesses operating in rigorous environments.

Common Challenges and Solutions When Using Needle Thrust Bearings

Needle thrust bearings are critical components in various high load applications, but they often come with their share of challenges. One common issue is the misalignment during installation, which can lead to uneven load distribution and premature wear. According to a report by the National Institute of Standards and Technology (NIST), improperly aligned bearings can experience up to 30% reduced load capacity, making precise installation vital for optimal performance.

Another challenge is lubrication, as needle thrust bearings operate under substantial loads and can generate significant friction. Inadequate lubrication can lead to overheating and eventual failure. A study by the Society of Tribologists and Lubrication Engineers (STLE) highlights that using the correct type of lubricant can improve the bearing life by as much as 50%. Manufacturers recommend regularly scheduled maintenance and the application of advanced synthetic lubricants to mitigate this issue.

Bearing contamination is also a significant concern that can compromise the performance of needle thrust bearings. Foreign particles can embed themselves between the needles and the raceway, leading to increased wear and potential failure. According to a report from the American National Standards Institute (ANSI), maintaining a clean operating environment can reduce contamination-related failures by up to 40%, underscoring the importance of proper maintenance practices in extending the life of needle thrust bearings in high load applications.

Needle thrust bearings are specifically designed to handle

Needle thrust bearings are specifically designed to handle