What is a Needle Roller Bearing and How Does it Work in Machinery

Needle roller bearings are a specialized type of roller bearing that strategically utilize slender rollers to reduce friction between moving parts in machinery. Their unique design allows them to support higher loads while taking up less space than traditional roller bearings, making them an ideal choice for various applications in industries ranging from automotive to aerospace. Understanding the function and advantages of needle roller bearings is essential for engineers and technicians to optimize machinery performance and reliability.

In essence, a needle roller bearing consists of a series of long, thin rollers that make contact with the raceway surfaces. This configuration results in a larger load-bearing area compared to ball bearings, which enhances the overall strength and durability of the bearing system. These bearings effectively handle radial loads, and their lightweight nature further contributes to improved efficiency in machinery operations. By exploring the mechanics of needle roller bearings, one can appreciate their critical role in reducing wear, improving energy efficiency, and extending the lifespan of mechanical components.

What is a Needle Roller Bearing?

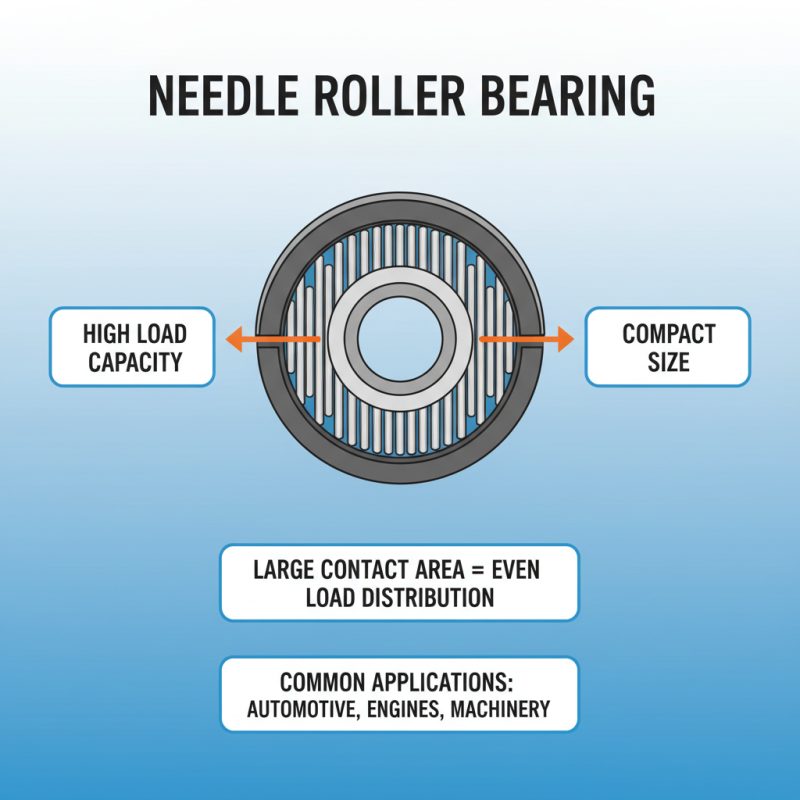

A needle roller bearing is a type of rolling-element bearing that uses long, thin cylinders called needles as its rolling elements. This design allows for a high load-carrying capacity while maintaining a compact size, making needle roller bearings particularly useful in applications where space is limited. The needles are positioned to provide a large contact area with the raceway, which helps to distribute load evenly and reduce stress on the bearing. Typically used in applications such as automotive transmissions, engines, and various types of machinery, needle roller bearings operate smoothly and efficiently, enabling machinery to perform optimally.

When selecting a needle roller bearing, it's essential to consider factors like load ratings, speed capabilities, and the type of lubrication required. Proper installation is also crucial to ensure that these bearings function effectively over time. Checking for alignment and adherence to proper tolerances can help in achieving the best performance.

Tips: Ensure that the bearing is adequately lubricated to facilitate smooth operation and minimize wear. Additionally, regular maintenance checks can extend the lifespan of needle roller bearings, preventing premature failure and ensuring operational efficiency. Always consult specifications to select the right type for your specific application, as using the incorrect size or type can lead to significant mechanical issues.

Key Components of Needle Roller Bearings

Needle roller bearings are crucial components in a variety of machinery, characterized by their ability to handle high radial loads while occupying minimal space. These bearings consist of thin, elongated rollers that distribute loads evenly across their surface area, which significantly reduces friction during operation. In essence, they serve as a compact solution for applications where space is limited but load capacity is essential.

The key components of needle roller bearings include the needle rollers themselves, the cage or separator, and the inner and outer rings. The needle rollers, typically measuring under 5 mm in diameter, are designed to maximize contact with the raceways, optimizing load-carrying capacities. The cage plays a vital role in maintaining the spacing between the rollers, preventing them from colliding and ensuring smooth rotation.

According to market research reports, the global needle roller bearing market is expected to grow by 5.2% annually, driven by an increasing demand in automotive and industrial applications. The development of advanced materials and coatings is also enhancing the performance and lifespan of these critical components, further solidifying their role in high-performance machinery.

How Needle Roller Bearings Work in Machinery

Needle roller bearings are essential components used in various machinery and equipment. Their design, featuring long and slender rollers, allows them to handle significant radial loads while occupying minimal space. This compact design is particularly beneficial in applications where space is a constraint, such as in automotive transmissions and industrial gear systems. The bearings operate by distributing loads evenly across the rollers, reducing friction and increasing efficiency in motion.

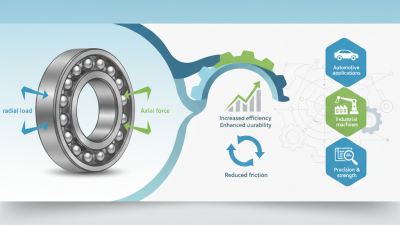

One of the key features of needle roller bearings is their ability to support both radial and axial loads. This versatility enhances their performance in dynamic situations where machinery faces varying forces. Proper lubrication is crucial for these bearings as it minimizes wear and tear, ensuring longevity and reliability. Regular maintenance of lubrication levels can significantly improve the efficiency of the machinery.

Tips: When selecting needle roller bearings for your application, consider the load capacity and the fit with other components. Ensure that the bearings are adequately lubricated to prevent overheating. Additionally, always check for any signs of wear and replace bearings that show excessive signs of damage to maintain optimal machinery performance.

Applications of Needle Roller Bearings in Various Industries

Needle roller bearings, known for their compact design and high load-carrying capacity, find extensive applications across various industries. Their unique structure, which utilizes long, thin rollers, allows for efficient operation in tight spaces, making them ideal for numerous machines. One common application is in automotive systems, where they support engine components and transmission designs, ensuring smooth operation under heavy loads. Additionally, they are prevalent in construction equipment, providing durability and reliability in harsh environments.

In the manufacturing sector, needle roller bearings are crucial for enhancing the performance of conveyor systems and assembly line machinery. Their ability to reduce friction and handle misalignment contributes to increased efficiency and lower maintenance costs. The aerospace industry also benefits from needle roller bearings, where their lightweight characteristics are essential for minimizing aircraft weight while maintaining robust performance.

Tips: When selecting needle roller bearings for specific applications, it is essential to consider factors such as load capacity, space limitations, and operational conditions. Regular maintenance and proper lubrication can significantly extend the lifespan of these bearings, ensuring optimal performance in your machinery. Additionally, consulting with engineers or industry experts can help in choosing the right type for your needs.

What is a Needle Roller Bearing and How Does it Work in Machinery - Applications of Needle Roller Bearings in Various Industries

| Industry |

Application |

Advantages of Needle Roller Bearings |

Load Capacity |

| Automotive |

Transmission systems |

Compact design, high load capacity |

Up to 1000 N |

| Aerospace |

Landing gear systems |

Lightweight, excellent fatigue resistance |

Up to 1500 N |

| Manufacturing |

Machine tools |

High precision, reduced friction |

Up to 800 N |

| Construction |

Excavators |

Durability, shock resistance |

Up to 1200 N |

| Robotics |

Joint actuators |

High torque, space-saving |

Up to 500 N |

Advantages and Limitations of Needle Roller Bearings

Needle roller bearings are widely known for their unique design which incorporates long and slender rollers that provide a high load-carrying capacity relative to their size. One of the primary advantages of needle roller bearings is their ability to fit into tight spaces while still supporting significant radial and axial loads. This makes them particularly useful in applications where there is limited room for larger bearing types. Moreover, their design aids in reducing friction between components, which enhances overall machinery efficiency and promotes longevity.

However, needle roller bearings are not without limitations. One notable drawback is their sensitivity to misalignment and load variations, which can lead to premature wear or failure if not managed properly. Additionally, they typically require more precise lubrication compared to other bearing types to prevent metal-to-metal contact, which can be more demanding in high-speed applications. Understanding these advantages and limitations is crucial for engineers and designers when selecting the appropriate bearing for specific machinery and ensuring optimal performance.