Understanding Industry Production Standards for Best Ball Bearings and Five Key Reasons for Their Importance

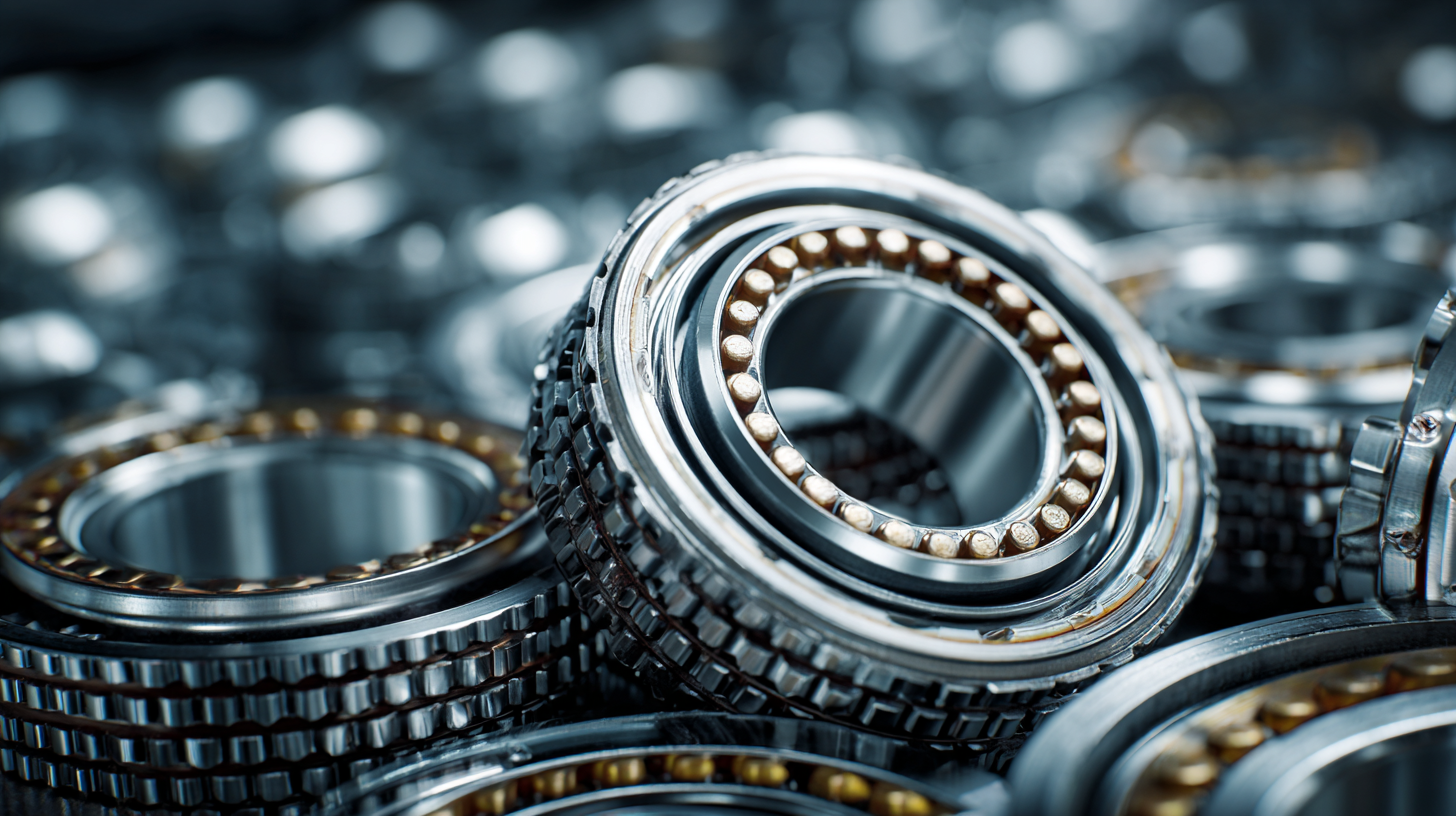

In the world of manufacturing and engineering, ball bearings play a critical role in ensuring the smooth operation of machinery and equipment. According to a recent report by the Global Ball Bearings Market Research, the industry was valued at approximately $60 billion in 2021, with projections indicating steady growth driven by advancements in technology and increased demand across various sectors. Understanding the production standards that govern the quality and performance of ball bearings is essential for OEMs and manufacturers alike, as these standards not only influence operational efficiency but also affect the longevity and reliability of machinery. In this ultimate guide, we will explore five key reasons why adhering to industry production standards for ball bearings is vital, highlighting their impact on performance, safety, and overall competitiveness in the marketplace.

The Significance of Industry Production Standards in Bearing Quality

Industry production standards play a pivotal role in ensuring the quality of ball bearings, which are essential components in a variety of applications, from automotive to aerospace. According to a report by the International Organization for Standardization (ISO), adherence to standardized production processes can reduce defects by up to 30%. This emphasis on quality assurance through strict manufacturing standards leads to improved performance and longevity of ball bearings, ultimately translating to enhanced operational efficiency across industries.

One crucial aspect underscoring the importance of these standards is the protection they offer against subpar materials and manufacturing practices. For example, the American Bearing Manufacturers Association (ABMA) emphasizes that bearings produced under non-compliant conditions can exhibit significantly reduced lifespan, resulting in costly downtime and repairs. By observing established industry standards, manufacturers not only fortify the integrity of their products but also safeguard end-users from the repercussions of inferior bearings.

Tip: Always check for certifications from recognized standards organizations when purchasing ball bearings to ensure you’re investing in quality.

Furthermore, standardization promotes consistency in the performance of ball bearings, which engineers rely on for precise functionality. A report from a leading industry journal highlighted that companies implementing stringent production standards witnessed a staggering 20% enhancement in product reliability. This raises the bar for competition while fostering a culture of excellence in manufacturing practices.

Tip: Regularly review supplier quality management systems to align with the latest industry standards and maintain the reliability of your machinery.

Identifying Key Attributes of Reliable Ball Bearing Suppliers

When sourcing ball bearings, understanding the key attributes of reliable suppliers is crucial for ensuring product quality and performance. A recent study from the International Federation of Bearing Manufacturers (IFBMA) indicates that over 70% of manufacturing inefficiencies stem from inadequate supplier selection. Therefore, companies must prioritize suppliers who showcase transparency in their production processes, adhere to international standards, and provide verifiable quality certifications.

One of the primary indicators of a trustworthy ball bearing supplier is their commitment to quality assurance. ISO 9001 certification, for instance, signifies a late adherence to quality management systems and has been linked to reduced defect rates in bearings. Moreover, a report from the American Bearing Manufacturers Association (ABMA) highlights that suppliers who implement advanced manufacturing technologies, such as automated inspection systems, experience up to a 30% decrease in manufacturing errors. Consequently, organizations aiming to enhance their production processes should meticulously evaluate potential suppliers based on their quality practices and technological capabilities to ensure they are partnering with industry leaders.

Understanding Industry Production Standards for Best Ball Bearings

This chart illustrates the key attributes of reliable ball bearing suppliers and their importance rating on a scale of 1 to 10. Material quality and dimensional accuracy are rated the highest, emphasizing their critical roles in the performance of ball bearings.

Essential Questions to Ask Potential Suppliers About Standards

When evaluating potential suppliers for ball bearings, it is crucial to ask the right questions to ensure compliance with industry production standards. For instance, inquire about the specific certifications they hold, such as ISO 9001, which signifies adherence to quality management systems. According to a report by the National Institute of Standards and Technology (NIST), manufacturers with ISO certifications demonstrate a 20% increase in product reliability and customer satisfaction compared to non-certified companies.

When evaluating potential suppliers for ball bearings, it is crucial to ask the right questions to ensure compliance with industry production standards. For instance, inquire about the specific certifications they hold, such as ISO 9001, which signifies adherence to quality management systems. According to a report by the National Institute of Standards and Technology (NIST), manufacturers with ISO certifications demonstrate a 20% increase in product reliability and customer satisfaction compared to non-certified companies.

Another essential question to pose is about their testing procedures and standards compliance. The American Bearing Manufacturers Association (ABMA) outlines various performance metrics that ball bearings must meet to ensure durability and efficiency. In fact, ball bearings that comply with ABMA performance standards typically have a 30% longer lifespan than those that do not. Understanding how suppliers conduct their quality assurance tests can help you gauge their commitment to providing high-quality products.

Lastly, it's valuable to ask about their sourcing of materials. Studies indicate that the type of materials used can significantly impact the bearings' performance and longevity. For example, high-grade steel bearings can outperform their lower-grade counterparts by up to 50% in fatigue strength. Carefully vetting suppliers based on these questions can lead to better procurement decisions and ultimately enhance operational efficiency.

Evaluating Supplier Compliance with Quality Assurance Protocols

In today's manufacturing landscape, evaluating supplier compliance with quality assurance protocols has become paramount, particularly in the production of high-performance ball bearings. According to recent data, approximately 70% of manufacturers report challenges in maintaining consistent standards across their supply chains. This highlights the need for robust compliance verification to ensure suppliers meet the required industry production standards.

A comprehensive evaluation of suppliers involves rigorous audits and assessments that align with established quality management principles. Various industry reports emphasize the importance of supplier sustainability and compliance checks, which can significantly reduce risks associated with procurement. By implementing these protocols, companies can mitigate potential disruptions and ensure that the materials used in ball bearing production adhere to the highest quality standards, ultimately affecting performance and safety in diverse applications.

Additionally, the integration of advanced technologies such as deep learning and machine learning aids in the selection and evaluation of suppliers, enhancing the overall quality management system. A recent study indicates that businesses utilizing such technologies can achieve up to a 30% improvement in supplier compliance rates, underscoring the critical role of compliance in achieving operational excellence. Thus, the commitment to evaluating supplier compliance is not merely a regulatory requirement but a strategic advantage in maintaining competitive edge in the industry.

Understanding Industry Production Standards for Best Ball Bearings and Five Key Reasons for Their Importance

| Standard Dimension |

Material Used |

Load Capacity (kg) |

Speed Rating (RPM) |

Compliance Standard |

| 608 |

Stainless Steel |

50 |

20,000 |

ISO 9001 |

| 6201 |

Chrome Steel |

60 |

16,000 |

ABEC 5 |

| 6902 |

Ceramic Hybrid |

70 |

24,000 |

ISO 14001 |

| Rolling Element |

Stainless Steel |

80 |

18,000 |

Global Quality |

| 6003 |

Carbon Steel |

45 |

15,000 |

TS16949 |

Comparative Analysis: Top Suppliers in the Ball Bearing Industry

The ball bearing industry is experiencing

significant growth, highlighted by a projected CAGR of over 9% from

2025 to 2032, with an anticipated market surpassing

USD 116.76 billion by 2032. This surge

reflects the increasing demand across various sectors, particularly in

automotive and industrial applications. As manufacturers

prioritize efficiency and reliability, the importance of adhering to

industry production standards has never been more crucial. These standards

ensure that ball bearings maintain performance and longevity, which is vital to

reducing maintenance costs and improving operational efficiency.

In this competitive landscape, understanding the top suppliers

in the ball bearing industry provides insights into market dynamics. Leading

manufacturers not only prioritize quality and adherence to production standards

but also invest in technological innovations to meet evolving customer demands.

For instance, the miniature ball bearings market, expected to reach

USD 2.25 billion by 2025, showcases the trend

towards smaller, yet more efficient components in high-precision machinery.

Similarly, the automotive wheel hub bearing aftermarket demonstrates a strong

growth trajectory, reflecting increasing vehicle production and the need for

quality replacement parts. This competitive analysis highlights how key players

are positioning themselves to capitalize on emerging opportunities within the

growing ball bearing market.

When evaluating potential suppliers for ball bearings, it is crucial to ask the right questions to ensure compliance with industry production standards. For instance, inquire about the specific certifications they hold, such as ISO 9001, which signifies adherence to quality management systems. According to a report by the National Institute of Standards and Technology (NIST), manufacturers with ISO certifications demonstrate a 20% increase in product reliability and customer satisfaction compared to non-certified companies.

When evaluating potential suppliers for ball bearings, it is crucial to ask the right questions to ensure compliance with industry production standards. For instance, inquire about the specific certifications they hold, such as ISO 9001, which signifies adherence to quality management systems. According to a report by the National Institute of Standards and Technology (NIST), manufacturers with ISO certifications demonstrate a 20% increase in product reliability and customer satisfaction compared to non-certified companies.