Exploring Innovative Alternatives to Best Thrust Roller Bearing for Global Buyers

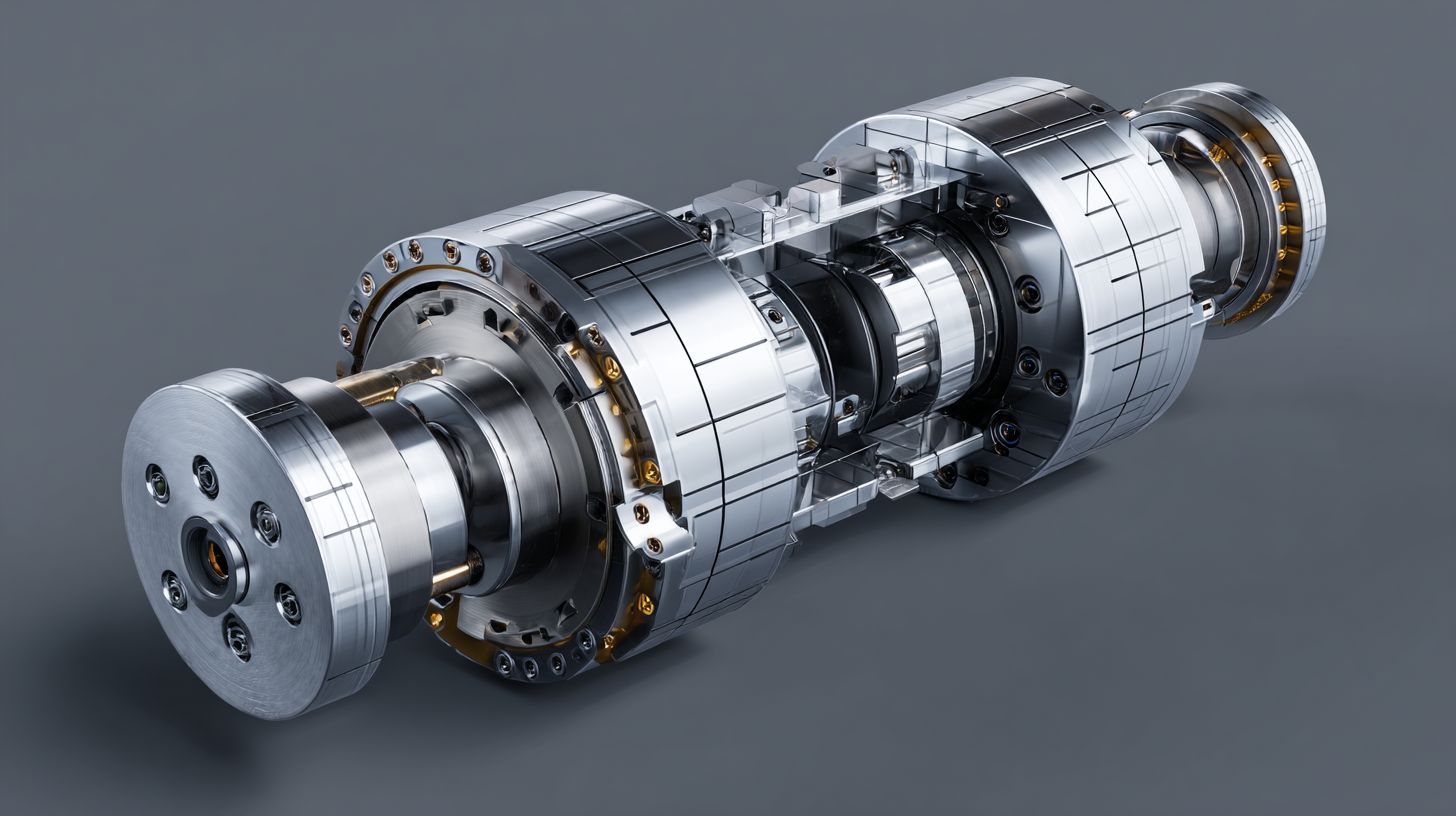

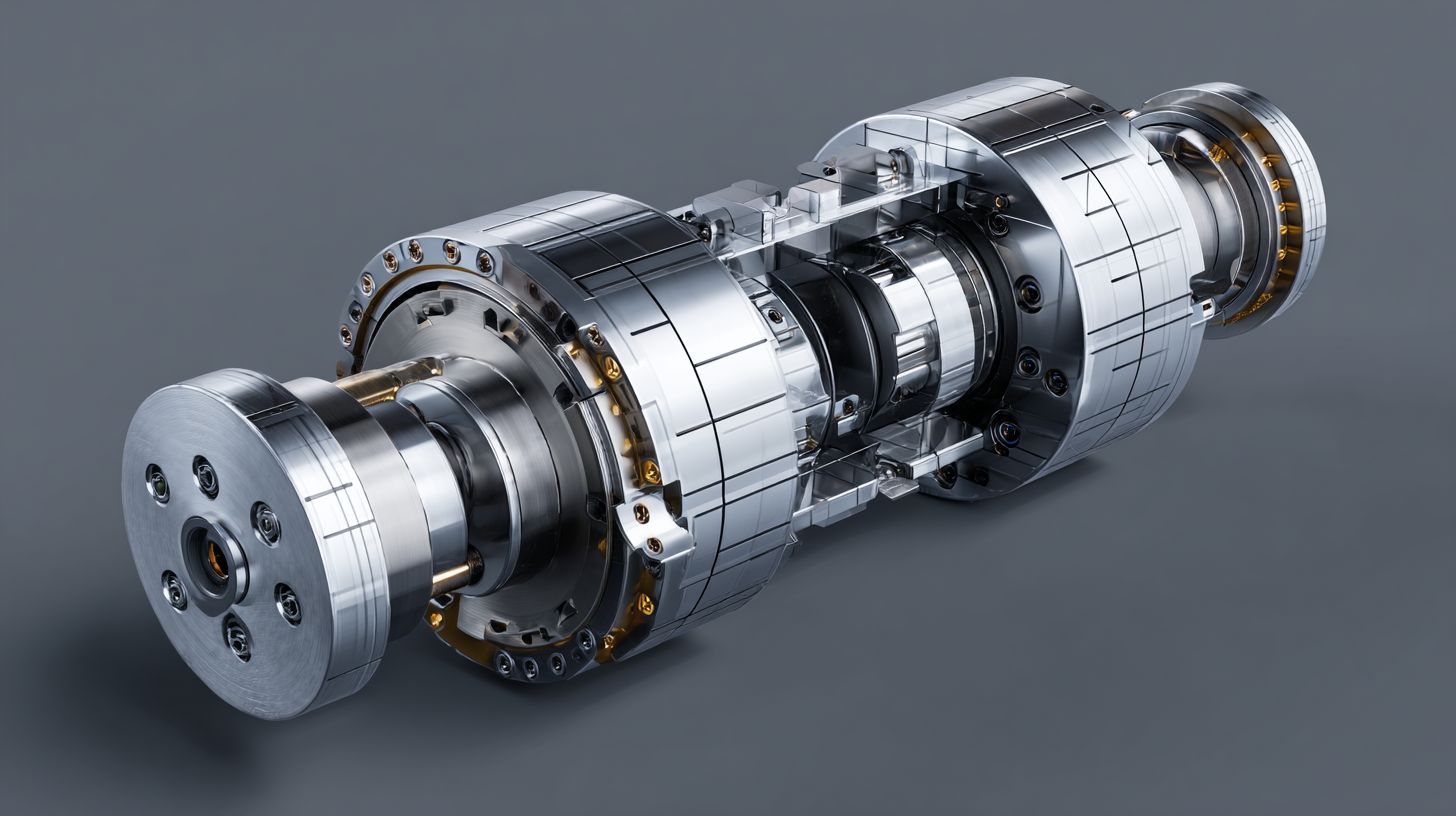

In the ever-evolving landscape of mechanical components, thrust roller bearings hold a crucial position, particularly in applications requiring the transmission of axial loads. However, as global buyers seek more innovative and efficient solutions, the demand for alternatives to traditional thrust roller bearings is surging. This blog delves into the emerging options that challenge the conventional best thrust roller bearing. By leveraging advancements in technology and materials, manufacturers are now offering new designs that enhance performance, durability, and efficiency.

In the ever-evolving landscape of mechanical components, thrust roller bearings hold a crucial position, particularly in applications requiring the transmission of axial loads. However, as global buyers seek more innovative and efficient solutions, the demand for alternatives to traditional thrust roller bearings is surging. This blog delves into the emerging options that challenge the conventional best thrust roller bearing. By leveraging advancements in technology and materials, manufacturers are now offering new designs that enhance performance, durability, and efficiency.

In an era where digitalization and smart manufacturing are redefining operational norms, understanding these alternatives will not only benefit buyers but also pave the way for more sustainable practices in the industry. Join us as we explore the latest trends and alternatives in thrust roller bearings, equipping global buyers with the knowledge to make informed decisions.

Innovative Bearing Solutions: A Guide to Thrust Roller Bearing Alternatives

Thrust roller bearings are widely used in various applications due to their ability to handle axial loads. However, in today's fast-paced industrial environment, buyers are increasingly seeking innovative alternatives that offer enhanced performance and unique benefits. This guide delves into some of the cutting-edge bearing solutions available to global buyers who aim to optimize their machinery’s efficiency while minimizing maintenance needs.

One noteworthy alternative is the use of spherical thrust bearings. Unlike traditional thrust roller bearings, these devices can accommodate misalignments and dynamic loads, making them an excellent option for applications subjected to irregular forces. Additionally, composite bearings made from advanced materials provide remarkable wear resistance and lower friction coefficients, which can significantly extend service life and reduce the need for frequent replacements. Moreover, magnetic bearing technologies are emerging as a futuristic solution, eliminating physical contact and thereby virtually eliminating wear altogether. Such innovations present multiple avenues for buyers looking to invest in long-lasting, efficient, and low-maintenance thrust solutions.

Market Trends: The Growing Demand for Advanced Bearing Technologies

The demand for advanced bearing technologies has significantly surged, driven by market trends that highlight the need for innovation in materials and functionality.

As per recent industry reports, the global bearing market is projected to expand from $500.16 billion in 2025 to approximately $971.0 billion by 2032, demonstrating a remarkable growth trajectory.

This growth trend is largely influenced by the increasing application of high-performance materials such as silicon, alumina, and zirconia, which provide enhanced durability and performance features necessary for applications ranging from bearings to grinding and valve systems.

Moreover, a shift towards inert and active functional materials is evident within the sector, catering to the evolving requirements of industries.

The super-precision bearing segment is particularly noteworthy, with a market size expected to reach $9.59 billion by 2025, showcasing a compound annual growth rate (CAGR) of 4.22% through 2033.

Additionally, the hybrid ceramic ball bearing market, currently valued at $3.6 billion in 2024, is anticipated to skyrocket to $55.2 billion by 2033.

This astonishing growth indicates a robust demand for cutting-edge bearing solutions that meet the rigorous standards of modern machinery and technology applications.

Case Studies: Successful Applications of Alternative Thrust Roller Bearings

In the quest for efficient machinery solutions, innovative alternatives to traditional thrust roller bearings have been gaining traction among global buyers. One standout case study involves a manufacturing plant that replaced conventional bearings with magnetic bearings. This shift not only reduced friction but also minimized maintenance costs, resulting in a significant increase in overall operational efficiency. By adopting this technology, the facility has been able to operate at higher speeds while ensuring reliability and performance.

When considering alternative thrust roller bearings, it’s crucial to evaluate the specific application requirements. One effective tip is to conduct a thorough analysis of load capacities and environmental conditions. This assessment helps in identifying the most suitable bearing type, whether it be polymer, magnetic, or ceramic bearings, each offering unique benefits tailored to distinct operational needs.

Another key takeaway from successful applications is the importance of collaboration with suppliers who specialize in advanced bearing technologies. Engaging with these partners can lead to customized solutions that address specific challenges in your operations. Always request case studies and performance metrics from suppliers to ensure you are making informed decisions that align with best practices in the industry.

Exploring Innovative Alternatives to Best Thrust Roller Bearing for Global Buyers

| Application |

Alternative Bearing Type |

Load Capacity (kN) |

Operational Temperature (°C) |

Material |

Used In |

| Wind Turbines |

Spherical Roller Thrust Bearings |

2500 |

-30 to 70 |

Steel |

Renewable Energy |

| Mining Equipment |

Tapered Roller Bearings |

3200 |

-20 to 80 |

Alloy Steel |

Heavy Machinery |

| Marine Applications |

Cylindrical Roller Bearings |

4000 |

-40 to 60 |

Stainless Steel |

Shipping and Transport |

| Automotive Industry |

Hybrid Roller Bearings |

3500 |

-20 to 100 |

Bimetallic |

Passenger Vehicles |

Performance Comparison: Traditional vs. Innovative Bearing Options

In industries where precision and reliability are paramount, selecting the right type of thrust roller bearing can significantly impact overall machinery performance. Traditional thrust roller bearings have long been the go-to option due to their robust construction and established reliability. However, emerging innovative bearing options are gaining traction, thanks to their ability to address some limitations of traditional designs. These innovative alternatives often feature advanced materials and technologies that enhance load capacity, reduce friction, and improve energy efficiency.

When comparing performance, one must consider factors like wear resistance, thermal stability, and lubrication needs. Traditional bearings typically depend on conventional materials that may not withstand extreme conditions, leading to shorter service lives. In contrast, innovative bearings incorporate cutting-edge composites and nanotechnology, enabling superior performance under various stress conditions. This evolution not only increases durability but also reduces maintenance costs in the long run, making them an attractive choice for global buyers looking for long-lasting and reliable solutions.

Future Outlook: The Role of Technology in Bearing Industry Innovations

As the bearing industry experiences rapid transformation, technology is emerging as a driving force behind innovation. The integration of advanced technologies, such as AI and laser processing, is reshaping manufacturing processes, enhancing efficiency, and improving product quality.

China stands at the forefront of this evolution, with its laser processing equipment market projected to reach approximately 89.9 billion in 2024. This growth, spurred by supportive policies, reflects the country's commitment to becoming a leader in high-tech manufacturing.

Moreover, the bicycle market is also witnessing shifts influenced by technological advancements. While the pandemic temporarily slowed the development of new products and trends, many companies continue to adapt, responding to growing consumer demands for diverse models and features.

This evolution signifies not only a competitive edge but also highlights the importance of innovation in meeting the complexities of modern consumer preferences.

As we move forward, a collaborative approach between traditional manufacturing and emerging technologies will be crucial for staying ahead in the dynamic landscape of the bearing and broader automotive industries.

In the ever-evolving landscape of mechanical components,

In the ever-evolving landscape of mechanical components,