What is a Double Row Ball Bearing and Its Advantages for Machinery

In the realm of modern machinery, the double row ball bearing has emerged as a pivotal component that enhances both efficiency and durability. According to Dr. Emily Carter, a leading expert in tribology and bearing technology, “The double row ball bearing not only provides increased load capacity but also significantly improves the stability of rotating machinery.” This sentiment underscores the critical role these bearings play in various applications, ranging from automotive to industrial machines.

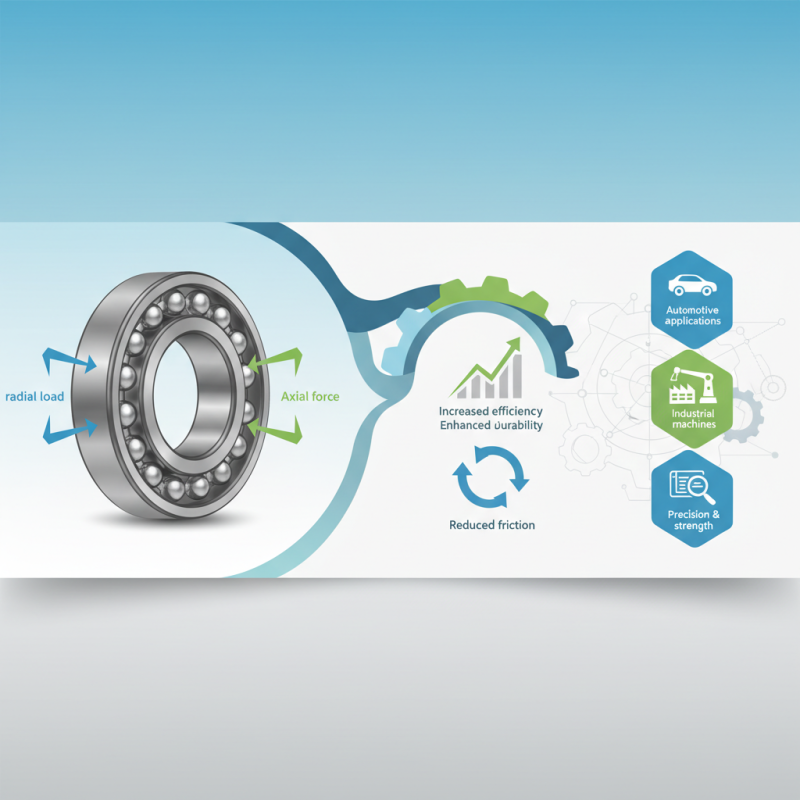

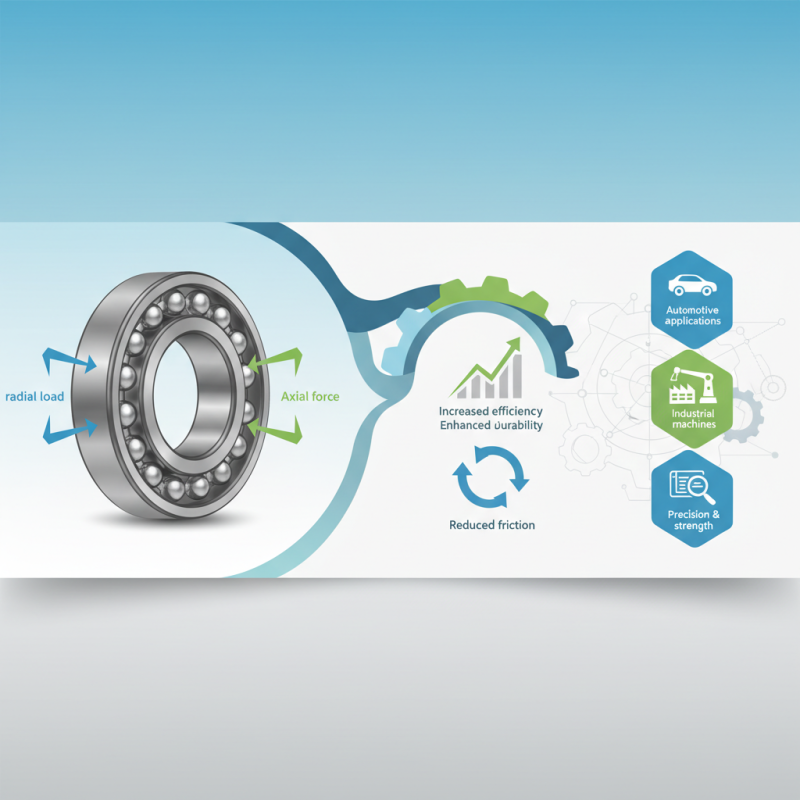

Double row ball bearings consist of two rows of balls that support radial loads while simultaneously accommodating axial forces. This design makes them particularly advantageous for applications where space is limited but a high level of precision and strength is essential. The unique configuration allows for a greater number of balls to be incorporated into the bearing, leading to enhanced load distribution and longer service life, making them an invaluable choice for today’s demanding engineering challenges.

As industries continue to evolve and seek advancements in performance and reliability, the importance of components like the double row ball bearing cannot be overstated. Their ability to reduce friction, increase efficiency, and improve overall mechanical stability positions them at the forefront of innovation in bearing technology, ensuring that machinery operates smoothly under a variety of conditions.

What is a Double Row Ball Bearing?

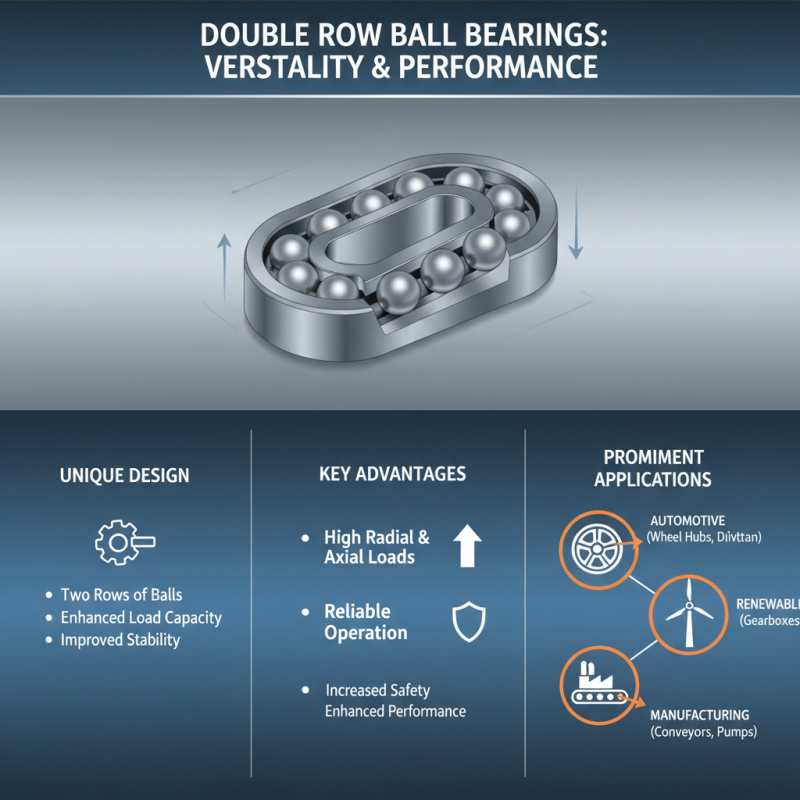

Double row ball bearings are a type of rolling-element bearing that features two rows of balls, providing enhanced load-carrying capabilities compared to single-row designs. These bearings are particularly effective in applications where both radial and axial loads are present. According to a report by MarketsandMarkets, the global ball bearing market is expected to grow from USD 27.8 billion in 2021 to USD 34.2 billion by 2026, driven by the increasing demand for efficient machinery and high-speed applications. This growth underscores the importance of double row ball bearings as industrial machinery evolves to meet stringent performance requirements.

One of the key advantages of double row ball bearings is their ability to accommodate higher loads while maintaining compact dimensions. By distributing the load across two rows, these bearings significantly reduce stress on each individual ball, resulting in improved durability and longer service life. Research by the International Journal of Mechanics adds that the use of double row ball bearings can lead to a reduction in overall machine maintenance costs, as their robust design can withstand harsher operating conditions and minimize the risk of failure. Additionally, the increased stiffness provided by this design allows for enhanced precision in high-speed applications, making them suitable for various industries, including automotive, aerospace, and manufacturing.

Components and Structure of Double Row Ball Bearings

Double row ball bearings are composed of two rows of balls that are arranged in a way to enhance load distribution and stability within machinery applications. These bearings typically feature an outer ring, two inner races, and a set of balls situated between them. The configuration not only allows for a greater load-carrying capacity compared to single row bearings but also provides better alignment and reduced friction during operation. The inner races are usually designed to accommodate the axial and radial loads efficiently, ensuring long-lasting performance.

In terms of structure, double row ball bearings utilize a sturdy outer race that houses the two rows of balls. This design enables them to withstand both radial loads and axial loads from both directions, making them ideal for applications that experience varying load conditions. Additionally, the spacing between the balls is optimized to minimize contact friction, thereby increasing efficiency and reducing wear over time. The integrated seals or shields often found on these bearings help to protect the internal components from contaminants, which further enhances their durability and performance in demanding environments.

What is a Double Row Ball Bearing and Its Advantages for Machinery - Components and Structure of Double Row Ball Bearings

| Dimension |

Value |

| Outer Diameter |

60 mm |

| Inner Diameter |

30 mm |

| Width |

15 mm |

| Load Capacity (Dynamic) |

3,500 N |

| Load Capacity (Static) |

5,800 N |

| Speed Limit |

5,000 RPM |

| Material |

Steel |

| Noise Level |

< 50 dB |

| Vibration Level |

< 0.5 mm/s |

Advantages of Double Row Ball Bearings in Machinery

Double row ball bearings are increasingly popular in various machinery applications due to their distinct advantages. One of the primary benefits is their ability to handle radial and axial loads simultaneously, which enhances the overall stability of machinery. This dual capacity allows for more compact designs, as machines can operate efficiently without the need for additional bearings to support different loads. Such efficiency is vital in sectors where space is limited and a higher load-carrying capability is required.

Another significant advantage of double row ball bearings is their improved rigidity and durability. The wider contact surface between the balls and raceways leads to a reduction in wear and tear over time, extending the bearing's lifespan. This feature is particularly important in heavy-duty applications where shock loads and vibrations are common. Furthermore, by minimizing friction and heat generation, double row ball bearings contribute to smoother operation and less downtime for maintenance, ultimately enhancing productivity in industrial settings.

Applications of Double Row Ball Bearings in Various Industries

Double row ball bearings are versatile components widely utilized across various industries due to their unique design and superior performance characteristics. These bearings consist of two rows of balls, offering enhanced load-carrying capacity and stability compared to their single-row counterparts. One of the prominent applications of double row ball bearings is in the automotive industry, where they are used in wheel hubs and drive trains. Their ability to withstand radial and axial loads makes them essential for the reliable operation of vehicles, contributing to increased safety and performance on the road.

In addition to automotive applications, double row ball bearings find extensive use in industrial machinery. They are commonly employed in equipment such as electric motors, pumps, and conveyor systems. Their robustness allows them to handle the demanding conditions often present in manufacturing environments, including high speeds and varying loads. Furthermore, the compact design of double row ball bearings helps optimize space in machinery, making them ideal for applications where minimizing footprint is critical. Overall, their adaptability across diverse sectors underscores the importance of double row ball bearings in modern engineering solutions.

Maintenance and Care for Double Row Ball Bearings

Maintaining double row ball bearings is crucial for ensuring optimal performance and longevity in machinery. Regular inspection is key; operators should look for signs of wear, such as unusual sounds or vibrations, that may indicate impending failure.

Lubrication plays a significant role as well; these bearings require proper grease or oil to minimize friction and prevent damage. It is essential to follow the manufacturer's guidelines for lubrication intervals and amounts to ensure efficient operation.

Cleaning is another important aspect of the maintenance routine. Dust, dirt, and other contaminants can accumulate within the bearings, leading to potential malfunctions. Periodic disassembly and cleaning using appropriate solvents help maintain cleanliness and functionality. Additionally, operators should ensure that the seals are intact to protect the bearing from external contaminants.

By adhering to these maintenance practices, the reliability and efficiency of double row ball bearings can be significantly enhanced, ultimately prolonging the life of the machinery they support.