How to Choose the Right Thrust Roller Bearing for Your Application?

Selecting the right thrust roller bearing is crucial for ensuring optimal performance in various applications. Renowned industry expert Dr. Emily Harper states, "The right bearing can make or break machine efficiency." This reflects the importance of careful consideration during the selection process.

Thrust roller bearings serve a specific function. They manage axial loads and offer stability in rotating machinery. These components play a vital role in sectors like automotive and industrial machinery. Yet, choosing one is often overlooked.

A mistake can lead to machine failure. It's essential to analyze load capacity, operating conditions, and required durability. Not every thrust roller bearing is suited for every task. Inadequate choices may lead to costly downtime and inefficiencies. Users must think critically about their specific needs.

Types of Thrust Roller Bearings and Their Applications

Thrust roller bearings come in various types, each designed for specific applications. These include cylindrical, spherical, and tapered types. Each variant supports axial loads well but behaves differently under specific conditions. For instance, cylindrical thrust roller bearings are ideal for high-load applications. They can handle large axial loads while maintaining stability.

Spherical thrust roller bearings excel in environments where misalignment may occur. Their design accommodates some angle variations, making them versatile. On the other hand, tapered thrust roller bearings offer a unique advantage. They allow for a range of axial and radial loads, making them suitable for dynamic applications. This flexibility can be beneficial but requires proper alignment during installation.

Tips: Always consider the load capacity needed for your application. This decision greatly influences performance. For critical setups, consultation with a bearing specialist can provide valuable insights. Evaluate the operating environment, as temperature and contamination can impact bearing life. Misalignment can lead to premature failure. Taking these factors into account can enhance your bearing choice. Always weigh trade-offs and take the time to choose wisely.

Key Factors to Consider When Selecting Thrust Roller Bearings

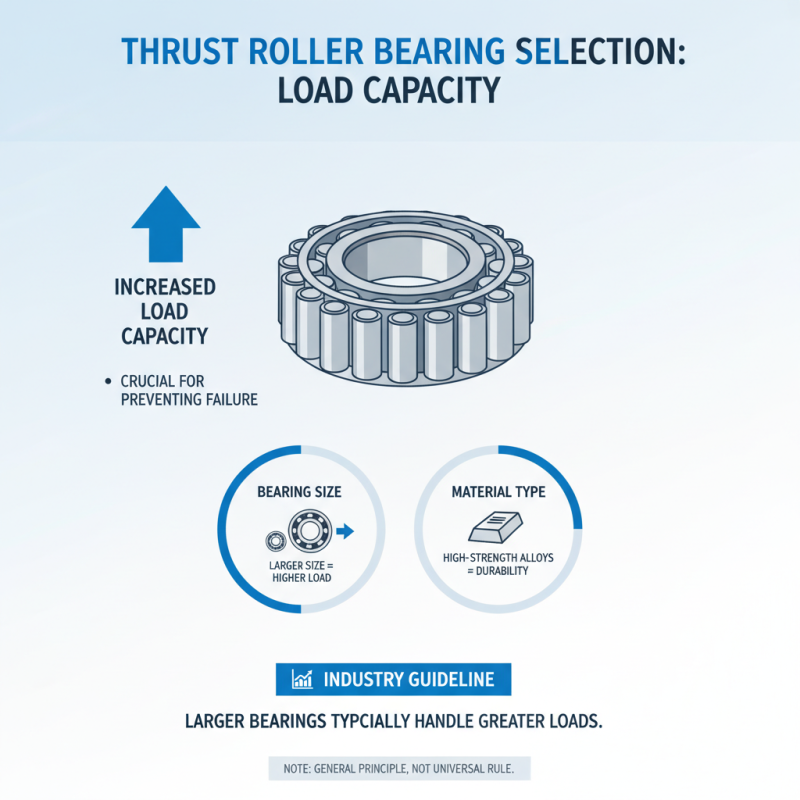

When selecting thrust roller bearings, consider the load capacity. The type of load—axial or radial—significantly impacts effectiveness. You need to assess how much weight the bearing will support. Different applications demand different capacities. Ensure you know the maximum load before making a choice.

Another important factor is the operating environment. High temperatures or moisture can affect bearing performance. Ensure the chosen bearing can withstand the conditions where it will be used. Think about lubrication and maintenance needs as well. Proper lubrication can prolong the lifespan of the bearing. However, some may overlook this key aspect.

Finally, the design and dimensions also matter. An improper fit can lead to premature wear. Always verify the size specifications before installation. This step is often overlooked, yet critical for optimal function. Make sure to review your options carefully. Taking these details into account will lead to a more suitable choice.

Material and Construction Considerations for Thrust Roller Bearings

Selecting the right thrust roller bearing can greatly impact performance. Material and construction play significant roles in this choice. Most thrust roller bearings are made from high-carbon chromium steel, showing excellent durability and strength. Reports indicate that 70% of bearing failures arise from material fatigue or environmental factors. Therefore, understanding these aspects is crucial.

Constructively, the design temperature is a key factor. Many bearings can withstand temperatures up to 120°C. Beyond this limit, material properties may deteriorate. An overlooked parameter is the lubrication method. Grease can work well, but it requires periodic maintenance. Studies show that incorrect lubrication accounts for 30% of bearing failures.

For specific applications, coatings like zinc or chrome might be beneficial. They can enhance corrosion resistance. However, they also add complexity. Evaluating the balance of cost and longevity is essential. This process might include a trial-and-error approach, which can be frustrating yet necessary. Ultimately, well-informed choices lead to better performance with thrust roller bearings.

Thrust Roller Bearing Material and Construction Considerations

Installation and Maintenance Tips for Optimal Thrust Roller Bearing Function

Proper installation and maintenance of thrust roller bearings are crucial for performance. A study by the American Society of Mechanical Engineers found that improper installation can reduce bearing lifespan by up to 50%. Ensuring correct alignment is essential; misalignment increases stress on the bearings. Use precision tools to check the alignment. Check the fitting surface for wear and tear to avoid issues down the line.

Routine maintenance is also vital for optimal function. Regularly inspect lubrication levels and replenish as needed. A survey indicated that over 40% of bearing failures are due to inadequate lubrication. Contaminated lubricants can cause significant wear. Keep the work area clean to minimize dirt ingress. If you notice unusual noises or vibrations, it’s a sign that something may be off.

Consider environmental factors too. Exposure to extreme temperatures or moisture can affect bearing performance. Regularly monitoring these conditions helps prevent unexpected failures. Even slight deviations in installation can lead to complications later on. Awareness in these areas is key for sustaining thrust roller bearing function.