How to Choose the Right Flat Bearings for Your Industrial Applications

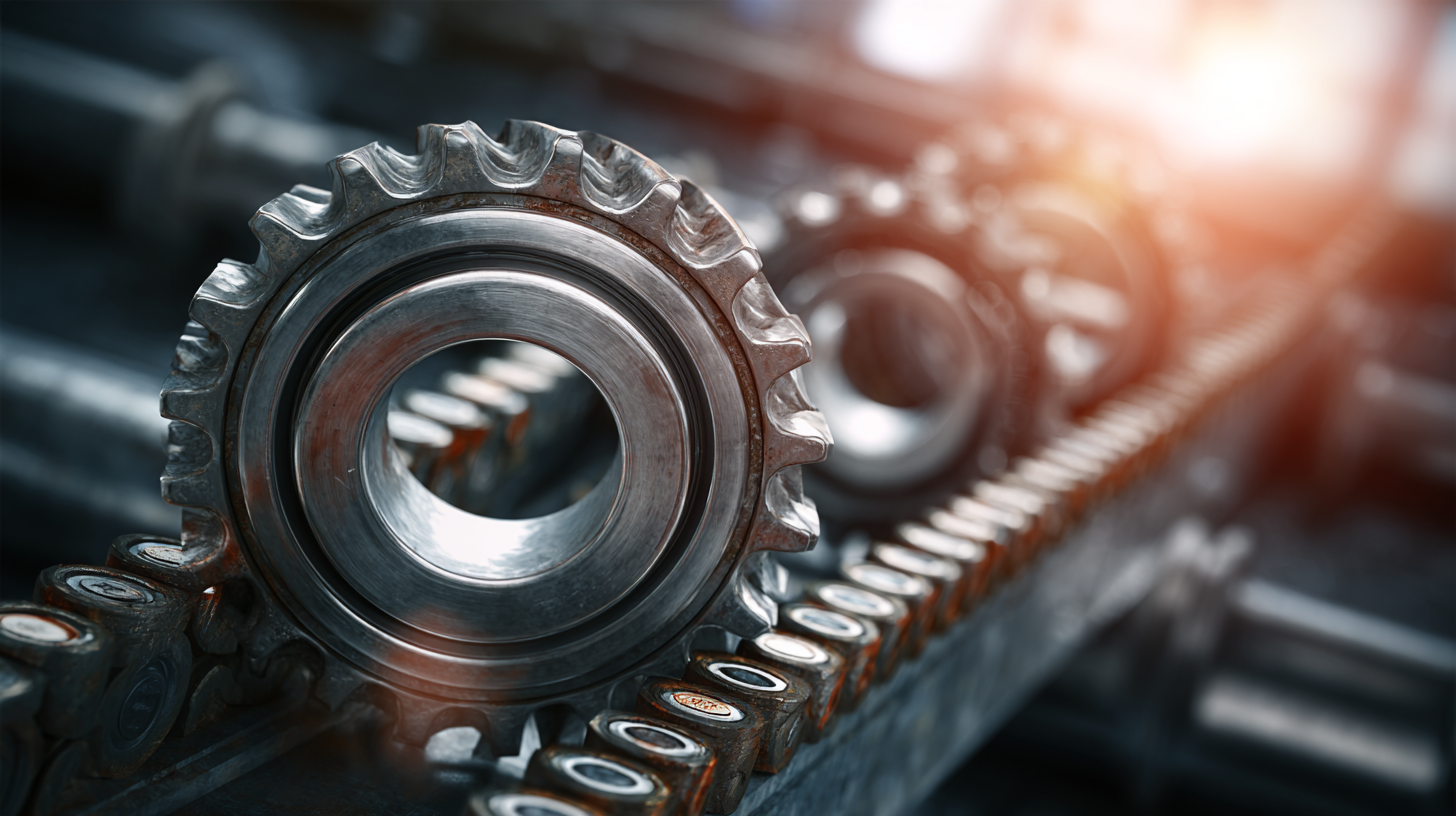

In the realm of industrial applications, the choice of components can significantly impact operational efficiency and equipment longevity. Among these components, flat bearings play a crucial role, providing essential support in a variety of machinery, from conveyor systems to automation equipment. According to a recent market analysis by Grand View Research, the global bearings market is projected to reach USD 82.5 billion by 2025, with a notable segment focused on flat bearings due to their ability to reduce friction and enhance performance. Proper selection of flat bearings not only ensures optimal functionality but also maximizes productivity, making it imperative for engineers and procurement specialists to understand the specific requirements of their applications. In this guide, we will explore key factors to consider when choosing the right flat bearings, ensuring that your machinery operates at peak performance in an increasingly competitive industrial landscape.

Factors to Consider When Selecting Flat Bearings for Industrial Use

When selecting flat bearings for industrial applications, several key factors should guide your decision. First, it’s essential to consider the load capacity of the bearings. According to a report by The Wright Group, choosing bearings that can support the maximum expected loads is critical to ensuring longevity and reliability in operations. Bearings designed with robust materials, like stainless steel or high-grade polymers, typically provide superior performance under heavy loads, enhancing overall system efficiency.

Another crucial aspect is the operating environment in which the bearings will function. The condition of the environment—including temperature fluctuations, exposure to chemicals, and moisture levels—can significantly affect bearing performance. The International Bearing Association notes that over 30% of bearing failures are due to environmental factors. Therefore, selecting bearings with appropriate seals or coatings can protect them from contamination and extend their lifespan. Additionally, the speed requirements of your application must be evaluated, as different bearing designs are optimized for varying operational speeds, influencing both efficiency and noise levels in machinery.

How to Choose the Right Flat Bearings for Your Industrial Applications

| Bearing Type |

Load Capacity (lbs) |

Material |

Operating Temperature Range (°F) |

Ideal Applications |

| Steel Flat Bearing |

500 |

Steel |

-40 to 200 |

Heavy machinery, construction equipment |

| Plastic Flat Bearing |

150 |

Nylon |

-40 to 180 |

Food processing, textile machines |

| Bronze Flat Bearing |

350 |

Bronze |

-50 to 300 |

Automotive, marine applications |

| Ceramic Flat Bearing |

200 |

Ceramic |

-40 to 600 |

Aerospace, high-temperature environments |

| Composite Flat Bearing |

250 |

Composite Material |

-40 to 220 |

Robotics, conveyor systems |

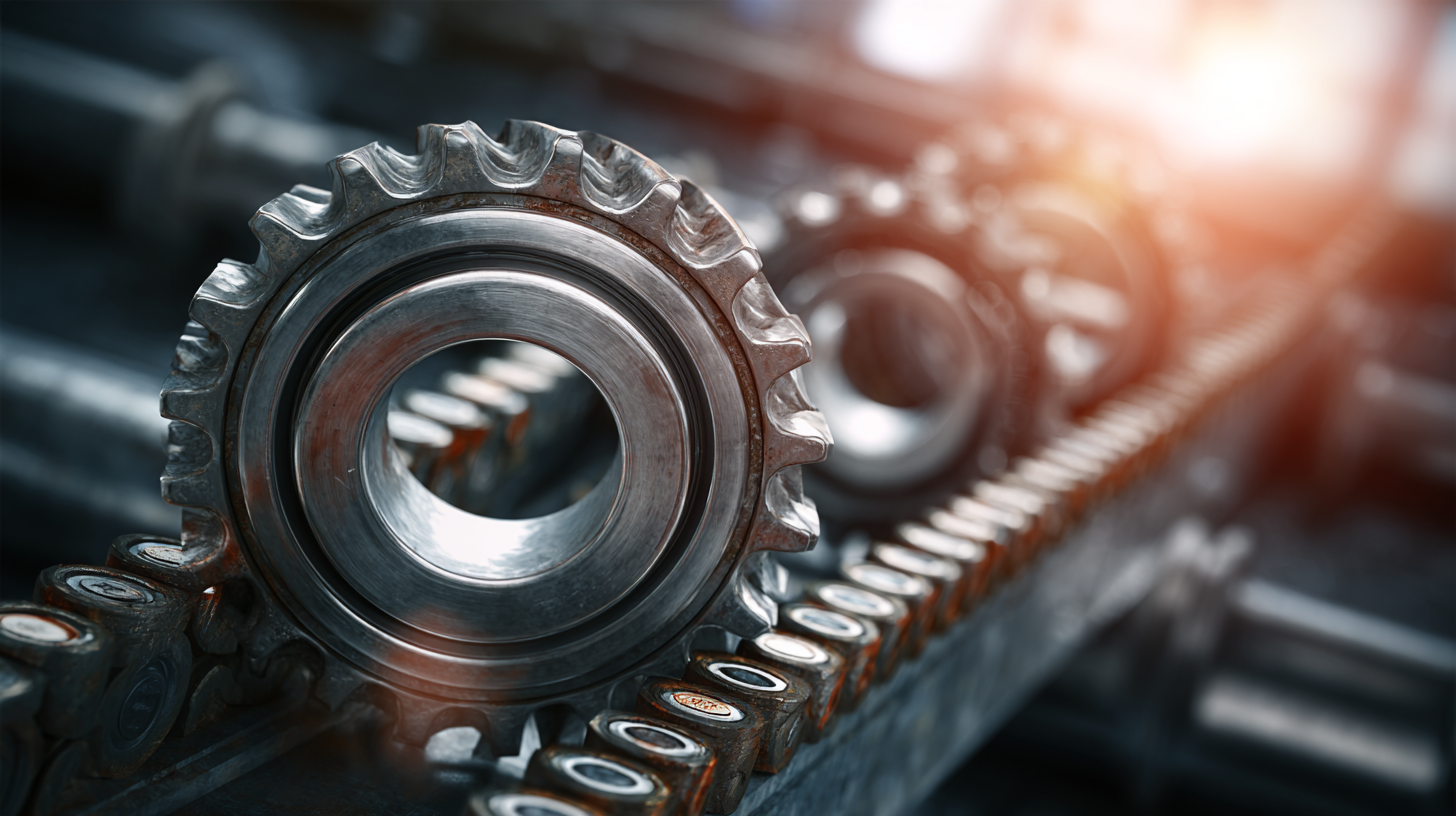

Understanding Load Capacities and Their Impact on Bearing Selection

When selecting the right flat bearings for industrial applications, understanding load capacities is crucial, as it directly impacts bearing performance and longevity. Load capacity refers to the maximum load a bearing can support without failure, which can be influenced by various factors such as material properties, design, and application conditions. For instance, newer methods like impact testing are being employed to evaluate the bearing capacity of structures, which can also be adapted to assess bearing performance in machines.

Tips: Always consider the operational environment when selecting bearings. Factors like temperature, lubrication availability, and exposure to contaminants can affect performance. Moreover, the integration of bionic design principles in bearing construction could offer innovative solutions, enhancing load capacities and operational efficiency. Conducting numerical analyses and simulations can provide valuable insights that guide your selection process, ensuring that the bearings you choose can handle the expected loads effectively.

Another critical aspect is to recognize that different applications may require varying types of load bearers. For example, while traditional bearings may suffice in some scenarios, advanced options like magnetorheological bearings can optimize performance under dynamic conditions, bringing significant benefits in terms of adaptability and reliability.

Load Capacities of Different Types of Flat Bearings

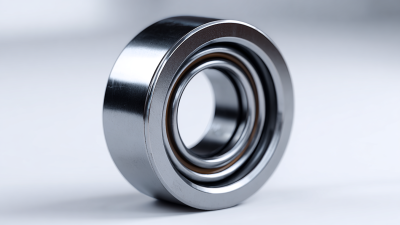

Material Choices for Flat Bearings: Balancing Durability and Performance

When selecting flat bearings for industrial applications, the choice of material is crucial in achieving an optimal balance between durability and performance. Typically, manufacturers utilize materials such as steel, nylon, and bronze, each presenting unique benefits tailored to specific operational environments. For instance, a report by the American Society of Mechanical Engineers (ASME) indicates that steel flat bearings can withstand loads up to 50% higher than those made from nylon, making them ideal for heavy-duty applications. However, while nylon offers excellent corrosion resistance and a lower coefficient of friction, it may not perform as effectively under high-temperature conditions.

Tips: Assess your operating environment before making a material decision. If your application involves exposure to moisture or chemicals, consider nylon or composite materials for their superior corrosion resistance. Conversely, for high-load applications, steel bearings will provide better load-bearing capabilities.

Moreover, the thickness and surface finish of the flat bearings can also greatly influence their performance. According to a study by the Bearings Industry Association, bearings with a smooth surface finish can enhance operational efficiency by reducing frictional losses by up to 15%. Therefore, investing in high-quality surface treatments can lead to longer service life and reduced maintenance costs.

Tips: Always evaluate manufacturer specifications and seek bearings with suitable finish characteristics for your specific application needs to ensure longevity and reliability.

The Role of Precision in Flat Bearings and Its Effect on Operational Efficiency

When selecting flat bearings for industrial applications, the precision of these components plays a crucial role in ensuring operational efficiency. A higher degree of precision in flat bearings translates to reduced friction, improved load distribution, and minimized wear over time. In applications where machinery operates at high speeds or under heavy loads, the importance of precision becomes even more pronounced. Utilizing precision-engineered flat bearings can significantly enhance the lifespan of equipment and reduce downtime.

**Tips:** When choosing flat bearings, it is essential to consider the specific requirements of your application, including load type and speed. Always look for manufacturers that guarantee tight tolerances and testing standards, as this can affect the performance dramatically. Additionally, regular maintenance checks can help identify any potential misalignments or wear issues early on, ensuring that the bearings operate within their optimal parameters.

Incorporating high-quality flat bearings into your industrial setup not only fosters smoother operations but also boosts overall productivity. The right bearings reduce energy consumption and can lead to substantial savings in operational costs. Therefore, investing time and resources into selecting the right flat bearings is a strategic move for any industrial operation aiming for longevity and efficiency.

Evaluating Environmental Conditions and Their Influence on Bearing Performance

When selecting the right flat bearings for industrial applications, understanding the environmental conditions they will be exposed to is crucial. Different environments can significantly influence bearing performance, including aspects such as temperature fluctuations, humidity levels, and the presence of contaminants. For example, in aerospace applications, advanced materials like CF/PEKK composites are tested under varying thermal and hygrothermal conditions to ensure their durability and reliability. Such studies underline the importance of evaluating how bearable conditions can affect not just individual components but the entire operational efficiency of the systems they are part of.

Moreover, environmental factors like climate change are playing an increasingly vital role in material performance assessments. Research has shown that the performance of infrastructure, such as flexible pavements, can be impacted by changing climates, highlighting the need for resilient materials that can withstand these pressures. Similarly, understanding the tribological behavior of bearing steels under poor lubrication conditions can reveal critical insights into how flat bearings might react when subjected to harsh environments. Thus, when choosing flat bearings, it is essential to consider the broader context of environmental influences to optimize their functionality and lifespan within specific industrial applications.