How to Choose the Right Double Roller Bearing for Your Needs?

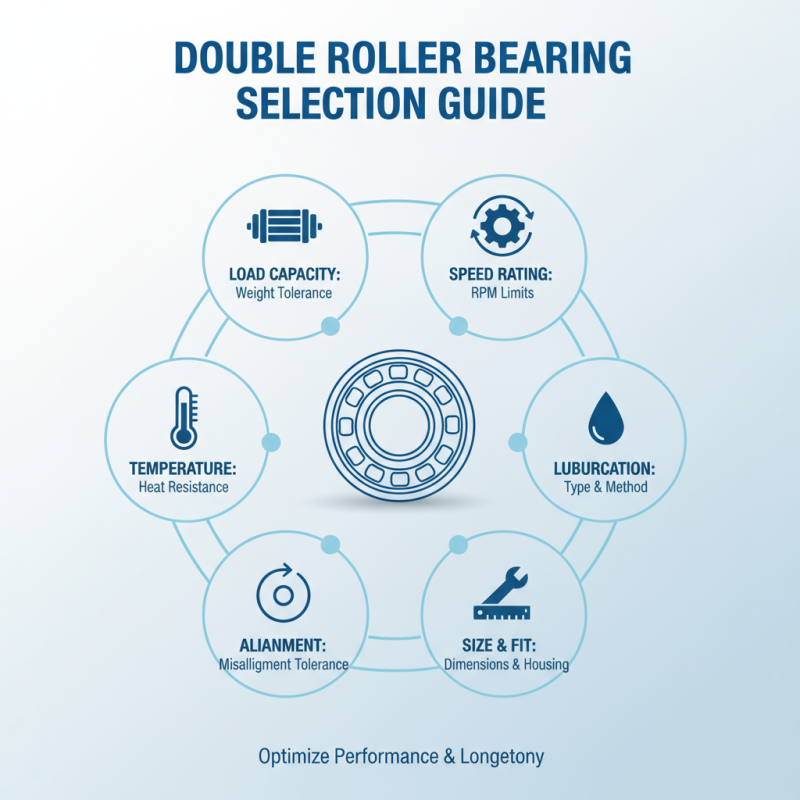

Choosing the right double roller bearing is crucial for various applications. These components support and guide rotating parts effectively. When selecting a double roller bearing, consider the load capacity, speed, and environment. Each application has unique demands that must be met.

Factors often overlooked include lubrication and temperature variations. A wrong choice can lead to premature failure or suboptimal performance. Ask yourself: does the bearing fit your machinery's needs? Is it suited for the expected loads? An acceptable double roller bearing should handle shock loads and resist wear.

Some may rush this decision. Take your time. Understanding specifications is vital. It can save costs and prevent frequent replacements. Choosing wisely now can lead to better efficiency and lower maintenance down the line.

Understanding the Basics of Double Roller Bearings and Their Applications

Double roller bearings are essential components in many mechanical systems. They provide stability and efficiency in operations. These bearings typically consist of two rows of rollers. They are designed to handle both axial and radial loads. This versatility makes them popular in various industries.

Understanding the basics of double roller bearings starts with knowing their applications. They are commonly used in conveyor systems and heavy machinery. In applications requiring high load capacity, these bearings thrive. However, choosing the right bearing can be challenging. Factors like load type, speed, and environmental conditions come into play. Manufacturers often overlook these aspects, leading to poor performance.

It's crucial to evaluate your specific needs before selection. A misstep can result in increased wear or even failure. Consider the bearing's material and design. Sometimes, the most suitable option might not be the obvious choice. Researching options and seeking expert advice can provide clarity. Even seasoned engineers must reflect on their choices. Mistakes can be costly, and understanding the nuances is key.

How to Choose the Right Double Roller Bearing for Your Needs?

This chart illustrates the common applications and load capacities of double roller bearings in various industries, helping you understand what to consider when selecting the appropriate bearing for your needs.

Key Factors to Consider When Selecting Double Roller Bearings

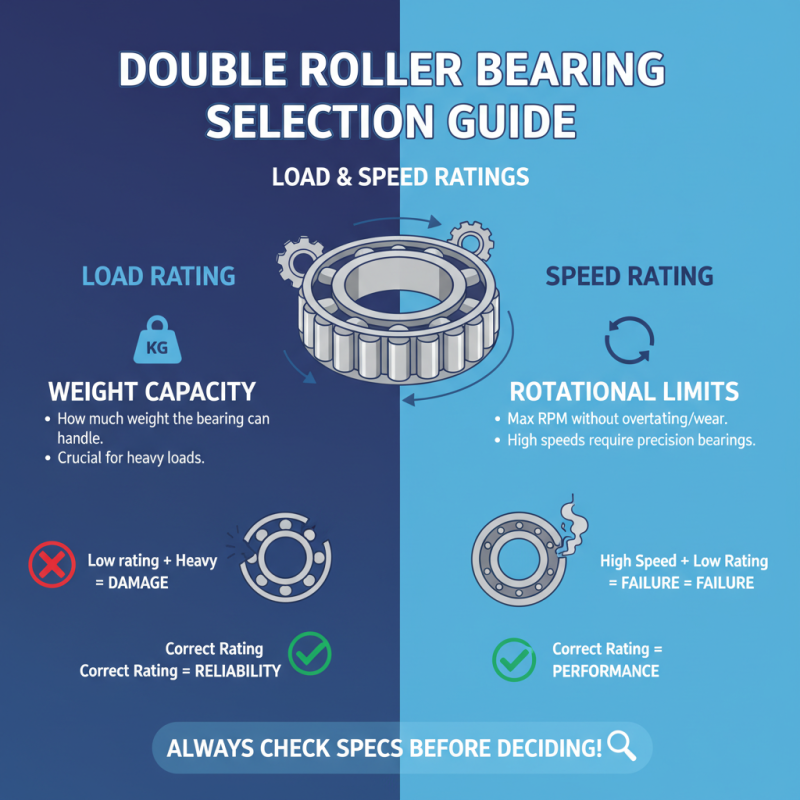

Choosing the right double roller bearing can be challenging. Several key factors will influence your decision. First, consider the load capacity. This determines how much weight the bearing can handle. If you exceed this limit, performance will drop.

Next, look at the speed rating. Higher speeds generate more heat and require specific bearings designed to handle such conditions. You should not ignore the material. Some materials are more resistant to wear and corrosion. This choice affects the lifetime of the bearing.

Compatibility is also crucial. Make sure the bearing fits your equipment. A mismatch can lead to premature failure. It's vital to consult technical specifications. Finally, don’t overlook the installation process. Improper installation can create problems. Sometimes, less experience leads to mistakes. Reflect on your choices carefully to avoid costly errors.

Material Choices and Their Impact on Bearing Durability and Performance

Choosing the right material for double roller bearings is crucial. Different materials can significantly impact durability and performance. Common materials include steel, ceramics, and polymers.

Steel offers excellent strength but can be prone to corrosion. Ceramics are resistant to wear but can be brittle. Polymers may provide lower friction but often lack the strength needed for heavy loads.

When selecting a material, consider the specific application. Will the bearing operate in a high-temperature environment? If so, ceramics may be the best choice. If the operation involves heavy loads, steel might be necessary despite its potential corrosion issues. Understand the demands of your project before making a decision.

It's also important to reflect on maintenance. Some materials require more attention than others. A poorly maintained bearing, regardless of its material, can lead to failure. Think about accessibility for maintenance tasks. A robust bearing material might not save you from issues if you can't reach it for upkeep. Balancing performance, durability, and maintenance flexibility is essential.

Maintenance Practices for Extending the Lifespan of Double Roller Bearings

Maintaining double roller bearings is crucial for their longevity. Regular inspection can help identify potential issues early. It's essential to check for signs of wear or damage. Listen for unusual noises while the equipment is running. These signals often indicate that maintenance is needed.

Lubrication plays a significant role in preserving the bearings. Applying the right type of lubricant keeps friction low and prevents overheating. Be careful not to over-lubricate. Too much grease can lead to rolling resistance and increased heat. Follow recommended intervals for re-lubrication, but don't be afraid to adjust based on operating conditions.

Cleaning is another important practice. Dust and debris can cause premature failure. Use appropriate cleaning agents and methods to avoid damaging the bearings. Encourage a clean work environment to minimize contamination. Remember, regular maintenance routines require discipline and commitment. Skipping these steps can lead to costly replacements later. Always reflect on what more can be done for better upkeep.