How to Choose the Right Needle Roller Bearing for Your Application

In the realm of mechanical engineering and industrial applications, the selection of the appropriate needle roller bearing is crucial for optimizing performance and enhancing equipment longevity. According to a recent report by MarketsandMarkets, the global needle roller bearing market is projected to reach USD 5.6 billion by 2026, driven by the increasing demand from automotive and manufacturing sectors. These bearings play a vital role in minimizing friction and maximizing load-carrying capacity, making them indispensable in applications ranging from electric motors to heavy machinery. However, with various designs and specifications available, choosing the right needle roller bearing requires a thorough understanding of factors such as load ratings, lubrication requirements, and operating conditions. This guide aims to equip engineers and decision-makers with essential insights to make informed choices, ensuring reliability and efficiency in their applications.

In the realm of mechanical engineering and industrial applications, the selection of the appropriate needle roller bearing is crucial for optimizing performance and enhancing equipment longevity. According to a recent report by MarketsandMarkets, the global needle roller bearing market is projected to reach USD 5.6 billion by 2026, driven by the increasing demand from automotive and manufacturing sectors. These bearings play a vital role in minimizing friction and maximizing load-carrying capacity, making them indispensable in applications ranging from electric motors to heavy machinery. However, with various designs and specifications available, choosing the right needle roller bearing requires a thorough understanding of factors such as load ratings, lubrication requirements, and operating conditions. This guide aims to equip engineers and decision-makers with essential insights to make informed choices, ensuring reliability and efficiency in their applications.

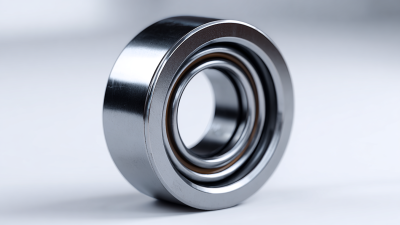

Understanding the Basics of Needle Roller Bearings and Their Applications

Needle roller bearings are a vital component in many mechanical systems, known for their ability to handle both radial and axial loads while maintaining a compact design. Unlike conventional bearings that utilize larger rolling elements, needle roller bearings employ long, slender rollers, which significantly reduce friction and increase load capacity. According to a report from MarketsandMarkets, the global needle roller bearing market is projected to grow from $1.6 billion in 2020 to $2.2 billion by 2025, highlighting their increasing demand across various industries, including automotive, aerospace, and industrial machinery.

Needle roller bearings are a vital component in many mechanical systems, known for their ability to handle both radial and axial loads while maintaining a compact design. Unlike conventional bearings that utilize larger rolling elements, needle roller bearings employ long, slender rollers, which significantly reduce friction and increase load capacity. According to a report from MarketsandMarkets, the global needle roller bearing market is projected to grow from $1.6 billion in 2020 to $2.2 billion by 2025, highlighting their increasing demand across various industries, including automotive, aerospace, and industrial machinery.

When selecting a needle roller bearing for a specific application, several factors need to be considered. These include the bearing's load rating, size, and environmental conditions it will endure. For instance, a study by Timken found that needle roller bearings can handle up to 30% higher loads compared to comparable ball bearings, making them ideal for high-performance applications where space is at a premium. Additionally, considerations such as lubrication, housing design, and alignment play a crucial role in ensuring optimal performance and longevity of the bearing.

Understanding these fundamentals can help engineers and designers make informed decisions that enhance reliability and efficiency in their projects.

Key Factors to Consider When Selecting a Needle Roller Bearing

When selecting a needle roller bearing, it’s essential to consider several key factors that can significantly impact the performance of your application. The automotive needle roller bearing market alone is projected to exceed USD 2.9 billion in 2023, with an anticipated growth rate of 6.5% CAGR from 2024 to 2032. This highlights the increasing demand for high-quality bearings that meet specific application needs, which can include load capacity, space constraints, and operating conditions.

Another critical factor is the bearing's stiffness, which can greatly influence the performance of machinery under load. Recent research focusing on finite-element modeling has underscored the importance of understanding nonlinear radial stiffness for accurately predicting bearing behavior in various applications. As the global bearings market is expected to grow from USD 50.16 billion in 2025 to USD 97.10 billion by 2031, careful consideration of these factors during the selection process will be crucial in maximizing efficiency and durability in the intended application. This information is particularly relevant for companies looking to maintain a competitive edge in a rapidly evolving industry.

How to Assess Load Capacity and Performance Requirements

When selecting the right needle roller bearing for your application, assessing load capacity and performance requirements is crucial. According to the International Organization for Standardization (ISO), the basic dynamic load rating (C) is a key metric that determines how much load a bearing can withstand while rotating at a specified speed. For instance, the ISO 281 standard suggests that the bearing should be selected such that the equivalent dynamic load does not exceed 60% of the dynamic load rating to ensure prolonged service life.

Furthermore, it's important to consider the application’s specific conditions, such as the expected shock loads and operational speeds. A study by the LUBRICANT Institute suggests that needle roller bearings can support higher load capacities compared to other bearing types due to their larger contact area with the raceway. For example, needle roller bearings can typically handle radial loads of up to 600%, while maintaining minimal friction – a vital aspect for high-speed applications. Evaluating these parameters will aid in selecting the optimal bearing, ensuring efficiency and durability in your operational context.

How to Choose the Right Needle Roller Bearing for Your Application - How to Assess Load Capacity and Performance Requirements

| Bearing Type |

Load Capacity (kN) |

Speed Limit (RPM) |

Inner Diameter (mm) |

Outer Diameter (mm) |

Width (mm) |

| Drawn Cup Needle Roller Bearing |

25 |

5000 |

20 |

30 |

15 |

| Caged Needle Roller Bearing |

30 |

4500 |

25 |

35 |

18 |

| Needle Roller Bearing with Flanges |

20 |

6000 |

15 |

25 |

10 |

| Needle Roller Thrust Bearing |

15 |

3000 |

10 |

20 |

12 |

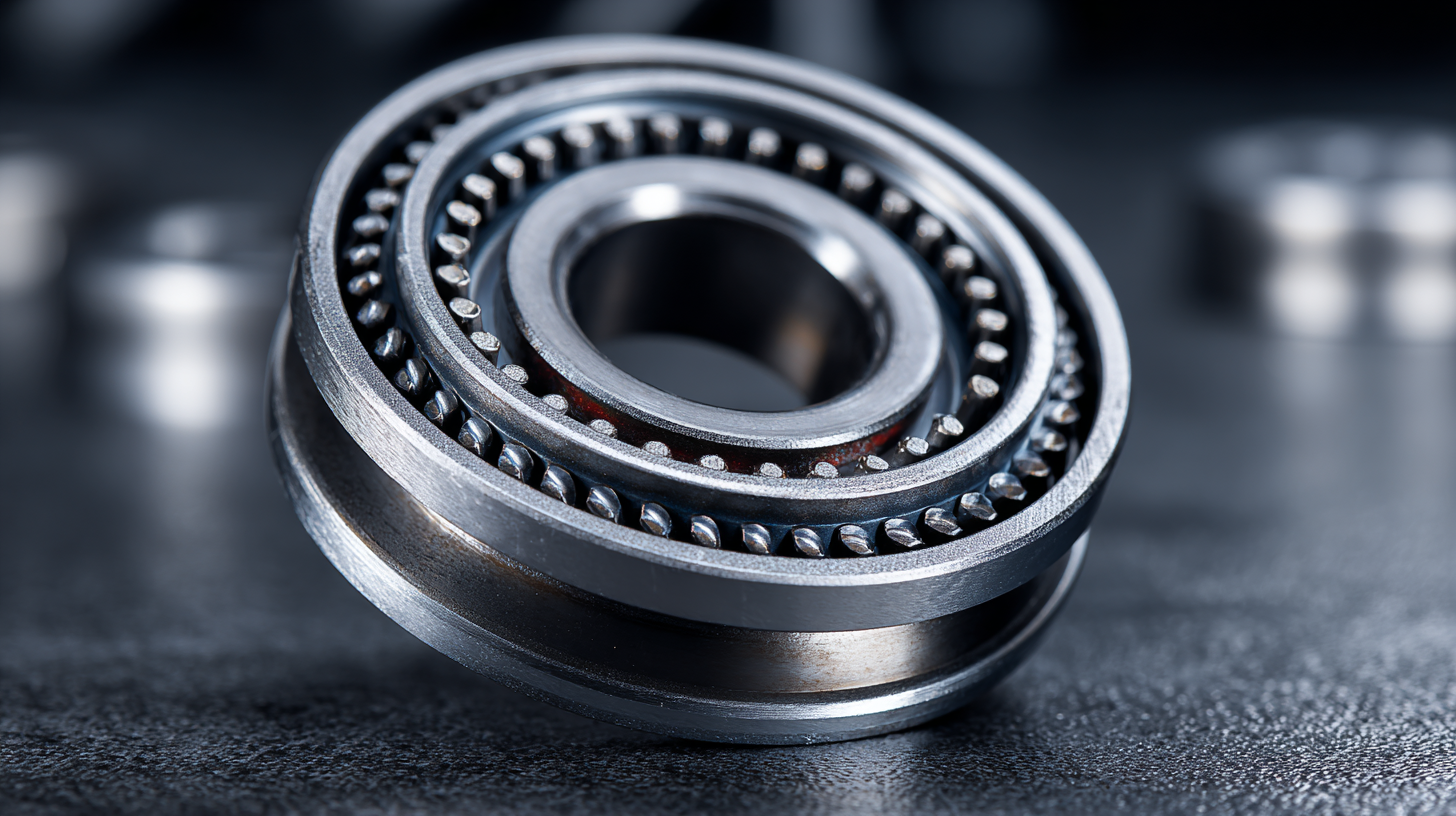

Material and Design Choices for Optimal Bearing Functionality

When selecting a needle roller bearing, understanding the materials and design choices is crucial for ensuring optimal functionality. Needle roller bearings are designed to accommodate heavy loads in a compact space, which makes the choice of material a fundamental factor. Common materials include steel and polymer, each offering distinct advantages. Steel bearings provide high strength and durability, making them ideal for applications requiring long service life and resistance to wear. In contrast, polymer bearings offer lightweight alternatives that are resistant to corrosion, suitable for environments where moisture or chemical exposure is a concern.

**Tip:** Consider the operating environment when selecting bearing materials. If the bearing will be exposed to harsh conditions, such as extreme temperatures or chemicals, opt for corrosion-resistant materials to enhance longevity.

Additionally, the internal design of the bearing plays a significant role in performance. Features like surface finishes and the configuration of the needle rollers can affect friction levels and load distribution. For applications with high speed, bearings with optimized roller alignment and reduced friction surfaces can lead to greater efficiency and lower thermal generation.

**Tip:** Evaluate your application's speed and load characteristics to determine if a specialized design, such as those with enhanced lubrication paths, would provide a significant performance benefit.

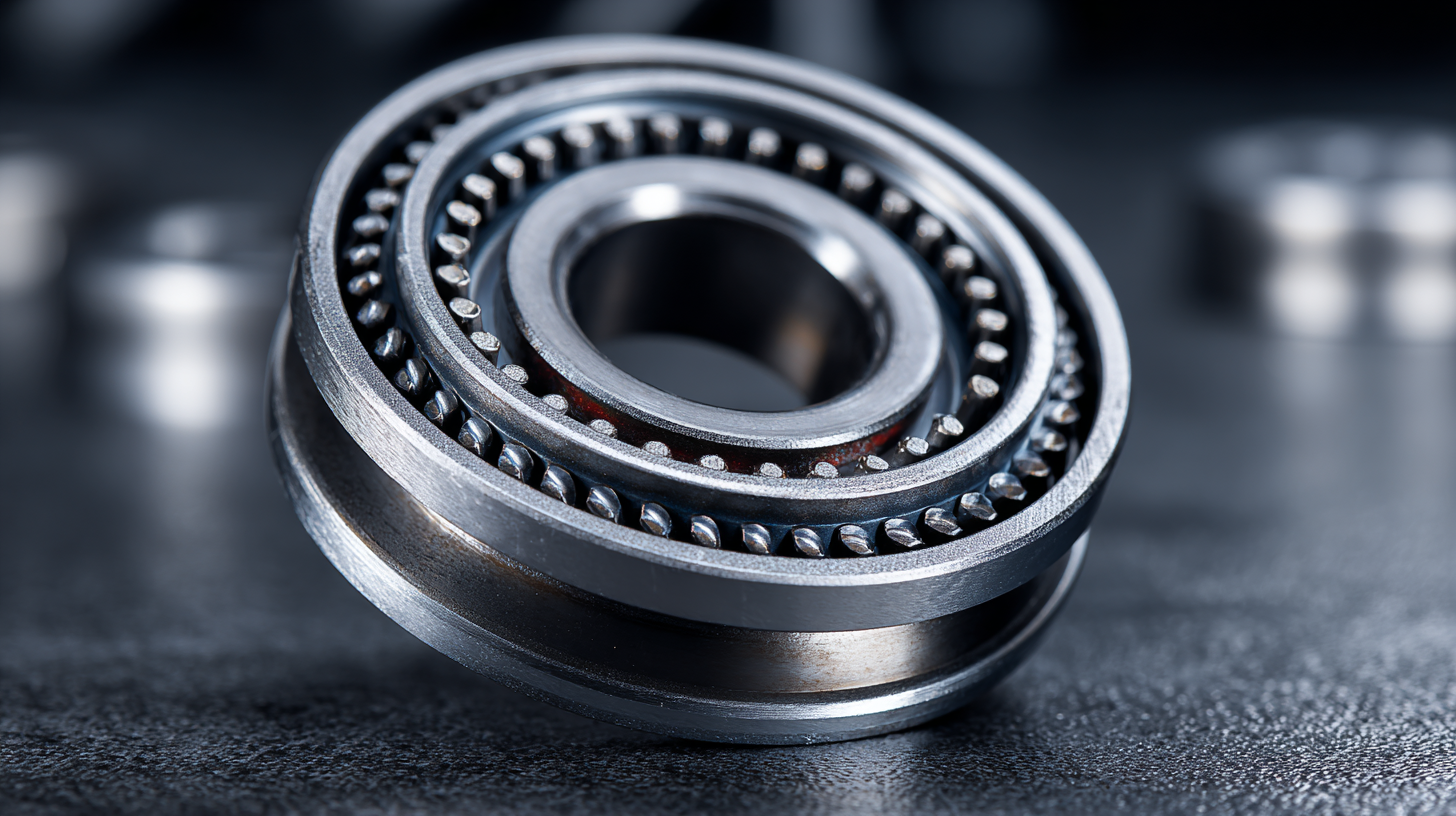

Common Mistakes to Avoid When Choosing Needle Roller Bearings

When selecting needle roller bearings, avoiding common pitfalls can significantly enhance performance and longevity. One prevalent mistake is underestimating load capacity. According to a report by the American Bearing Manufacturers Association (ABMA), proper load selection is crucial, as inadequate bearing ratings can lead to premature failure. Always assess the dynamic and static load ratings relevant to your application to ensure optimal performance.

Another commonly overlooked aspect is the importance of lubrication. Many engineers fail to understand that inadequate or inappropriate lubrication can drastically reduce bearing life. According to research from the National Lubrication Fund, 90% of bearing failures are attributed to lubrication issues. Selecting the right lubricant—whether it's oil or grease—based on your operational environment and bearing design can mitigate these failures and enhance reliability.

Finally, consider the bearing fit and alignment. Improper installation can lead to misalignment and excessive friction, impacting performance. The International Organization for Standardization (ISO) recommends adhering to specific tolerances during installation to maintain operational efficiency. Taking the time to evaluate these factors can prevent costly mistakes and ensure the needle roller bearing operates effectively within its intended application.

Needle Roller Bearings Selection Metrics

This bar chart displays the key factors to consider when selecting needle roller bearings for various applications. The data represents the relative importance of each factor on a scale from 1 to 10, helping guide users to avoid common mistakes in their selection process.

In the realm of mechanical engineering and industrial applications, the selection of the appropriate

In the realm of mechanical engineering and industrial applications, the selection of the appropriate