How to Choose the Right Cylindrical Bearing for Your Applications?

Choosing the right cylindrical bearing for your applications can be a daunting task. Industry expert John Smith once mentioned, "The right bearing makes all the difference." His words resonate deeply in the engineering community. Selecting the perfect cylindrical bearing is not just about specifications; it involves understanding your unique requirements.

Cylindrical bearings are often used in various applications. They can support radial loads and allow for high-speed operations. However, not all cylindrical bearings are created equal. You may face challenges, such as varying load capacities and material choices. These factors can significantly impact performance and longevity.

When seeking the ideal cylindrical bearing, careful consideration is essential. Think about the environment. Harsh conditions can deteriorate bearings quickly. Reflecting on real cases reveals that neglecting these details can lead to costly failures. Finding the right balance is crucial. Just because a bearing is highly rated does not mean it’s the best fit for your needs.

Understanding the Basics of Cylindrical Bearings and Their Applications

Cylindrical bearings are essential in many mechanical applications. They support rotating shafts while reducing friction. These bearings consist of a cylindrical outer ring and a rotating inner ring. Their design allows for smooth motion and stability. They can handle both radial and axial loads very well.

When selecting a cylindrical bearing, consider load capacity and speed. A high load capacity may be necessary for heavy machinery. Conversely, for high-speed applications, the bearing must be lightweight and durable. Material choice also impacts performance. Steel offers strength, while ceramic can reduce friction. Pay attention to the environment as well; factors like temperature and humidity can affect longevity.

Understanding your specific application is crucial. Each use case may require different specifications. For example, in automotive applications, compact size matters. In contrast, industrial machines may prioritize load capacity. Evaluate these needs carefully. It's important to reflect on potential trade-offs in performance versus durability. Sometimes, what seems ideal might not stand up under real-world conditions. Make sure to test the selected bearing under actual operating conditions before full-scale application.

Key Factors to Consider When Selecting a Cylindrical Bearing

Choosing the right cylindrical bearing requires careful consideration of several key factors. Load capacity is crucial. Ensure the bearing can handle the maximum load in your application. If the load exceeds capacity, premature failure is likely. Assess both radial and axial loads. This will help you understand the forces at play.

Another important factor is the operating environment. Consider factors like temperature, moisture, and contamination. Some bearings are suited for high temperatures, while others resist corrosion. If your application involves dirt or dust, ensure proper sealing. Loose seals can lead to failure.

Material selection also plays a role. Steel bearings offer high load capacity, yet may rust. Alternatives like ceramic provide better resistance but may not handle heavy loads. Each material has trade-offs. Look for a balance that meets your needs. Lastly, don't forget about lubrication. Proper lubrication extends lifespan. But be aware of the challenges in selecting the right type. Too much grease can lead to overheating; too little causes wear.

How to Choose the Right Cylindrical Bearing for Your Applications?

| Factor |

Description |

Importance Level |

Recommended Tolerance |

| Load Capacity |

The maximum load that the bearing can support during operation. |

High |

C3 |

| Speed Rating |

The maximum rotational speed for optimal performance. |

Medium |

P5 |

| Material |

Type of material used which affects durability and resistance. |

High |

Stainless Steel |

| Operating Temperature |

The temperature range within which the bearing operates effectively. |

Medium |

-20°C to 120°C |

| Clearance |

The internal clearance of the bearing affects its performance and life. |

High |

C0 |

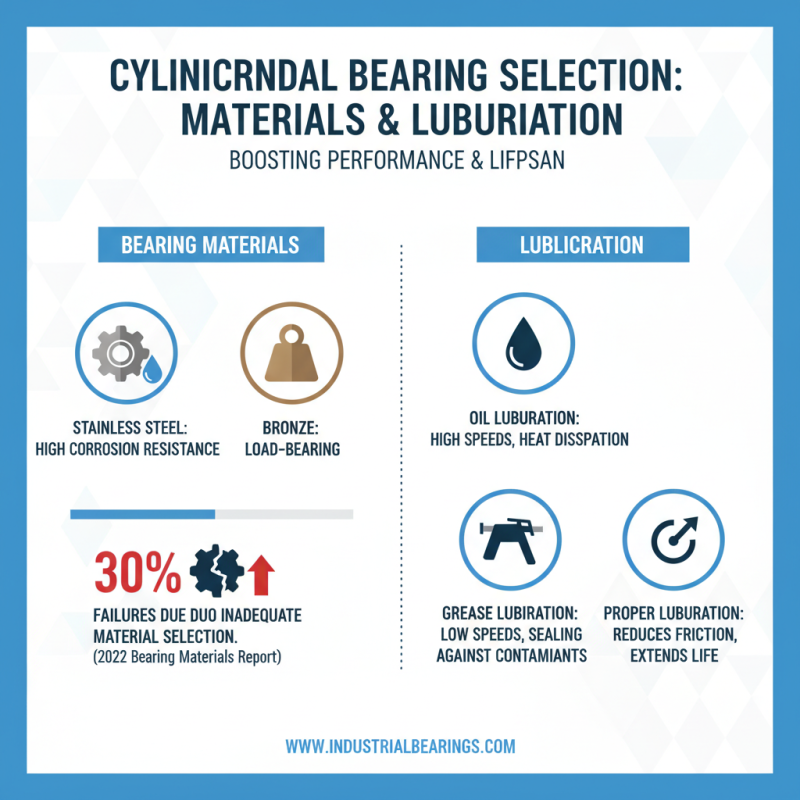

Materials and Lubrication Options for Cylindrical Bearings

When selecting the right cylindrical bearing for your application, materials and lubrication play a pivotal role. The material composition directly affects the bearing’s performance and lifespan. Common materials include stainless steel, which offers high corrosion resistance. Another option is bronze, known for its load-bearing capabilities. According to the 2022 Bearing Materials Report, around 30% of failures are due to inadequate material selection.

Lubrication is crucial for reducing friction and wear. Several options exist, like grease and oil, each with its benefits. Grease is typically easier to manage and convenient for sealed applications. However, oil offers more extensive heat dispersion. In a recent lubrication study, nearly 50% of equipment failures were linked to improper lubrication methods.

Tips: Always match the lubricant's viscosity to your operating environment. Periodically check for contamination in lubricants. Regular maintenance is key to preventing issues down the line.

Materials and lubrication must complement each other. An ideal combination enhances durability but requires careful consideration. Assess the load, speed, and environmental factors of your application. Some manufacturers report a drastic increase in efficiency by adapting specific materials and lubrication techniques. Avoid hesitation; make informed choices to ensure optimal function.

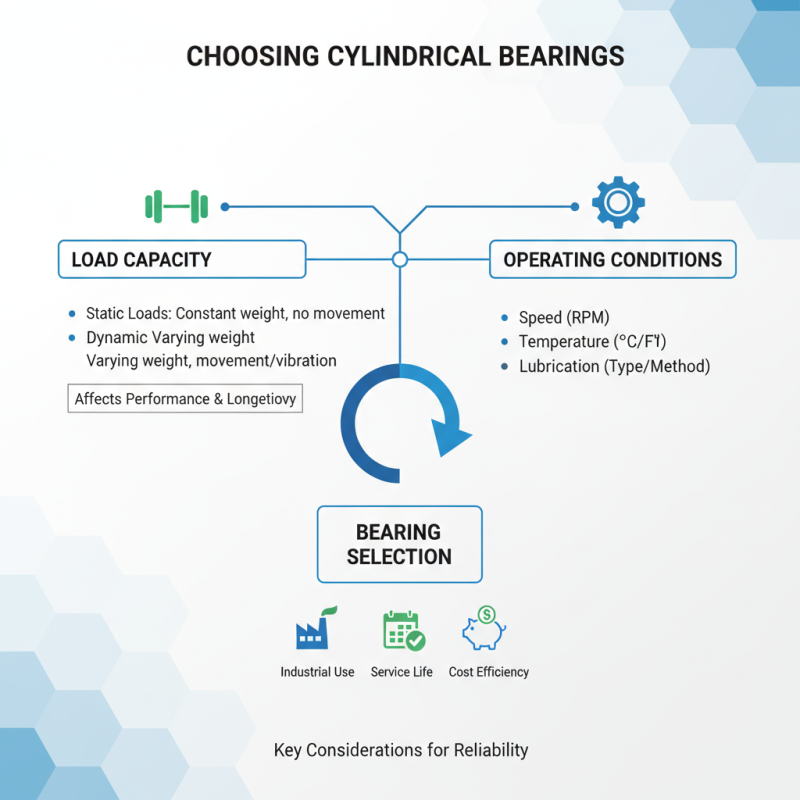

Evaluating Load Capacity and Operating Conditions for Bearings

Choosing the right cylindrical bearing involves evaluating load capacity and operating conditions. Load capacity is crucial. It determines how much weight the bearing can handle over its lifetime. This affects performance and longevity. Start by assessing the load types. Are they static or dynamic? Different loads require different bearings.

Operating conditions also play a significant role. Consider the environment. Is it humid, dusty, or high-temperature? These factors can impact bearing choice. For instance, bearings exposed to dirt may need better sealing. Pay attention to lubrication needs as well.

**Tips:** Check the load ratings on bearing specifications. This ensures they match your application. Evaluate how the load changes over time. Sometimes, it's not steady. Adaptability can save future issues. Conduct routine checks on your bearing's condition. It’s a good practice for maintenance. Don’t ignore small signs of wear, as they can lead to bigger problems.

Common Mistakes to Avoid When Choosing Cylindrical Bearings

Choosing the right cylindrical bearing can be tricky. Many people overlook important factors. Common mistakes often lead to inefficiencies. It’s crucial to evaluate the application first. Consider load requirements, speed, and environmental conditions. Ignoring these aspects will likely result in premature failure.

One common error is selecting a bearing based solely on size. While dimensions matter, other specifications are just as important. Material choice affects durability and performance. Using unsuitable materials may cause frequent replacements. Pay attention to lubrication needs too. Poor lubrication can lead to excessive wear.

Tips: Always double-check the bearing’s load rating. Ensure it's suitable for your specific application. Consider both static and dynamic loads. Inspect installation processes regularly. Misalignment can lead to significant issues. Remember, details matter in bearing selection. You don’t want a small oversight to derail your project.