China's Quality Upgrade in Best Cylindrical Roller Bearings Driving Global Sales Success

As we approach 2025, the global bearings market is witnessing a significant transformation, particularly in the cylindrical roller bearing segment, which has been identified as a critical component in various industries, including automotive and manufacturing.

According to a recent report by Markets and Markets, the global bearings market is projected to reach USD 186.8 billion by 2025, with cylindrical roller bearings expected to capture a significant share due to their enhanced load-carrying capacity and reliability.

China's strategic focus on quality upgrades in manufacturing has positioned it as a leading player in the supply of high-performance cylindrical roller bearings, thereby driving global sales success.

This blog will explore the technological advancements influencing the industry's trajectory and delves into the "How to" approaches that can harness these trends for competitive advantage.

China's Leadership in Cylindrical Roller Bearing Production: An Overview of Market Trends

China has emerged as a dominant player in the cylindrical roller bearing market, significantly impacting global sales dynamics. According to a report by MarketsandMarkets, the global bearing market is projected to reach USD 100 billion by 2025, with automotive and industrial applications driving much of this growth. As China's production capacity increases, the country holds nearly 23% of the global market share for cylindrical roller bearings, positioning it as a key supplier in various industries, including automotive, aerospace, and machinery manufacturing.

One of the defining factors of China's leadership in this sector is the focus on quality enhancement through advanced manufacturing technologies. Recent data from Technavio indicates that the adoption of smart manufacturing practices has led to a 15% reduction in production costs for leading Chinese manufacturers. This emphasis on innovation not only improves product reliability but also aligns with the increasing demand for high-performance bearings in precision machinery and equipment.

**Tip:** For companies looking to enhance their supply chains, consider sourcing cylindrical roller bearings from Chinese manufacturers that adopt ISO 9001 quality standards, as this ensures products meet international quality benchmarks.

**Tip:** Investing in high-quality bearings can lead to reduced maintenance costs and increased operational efficiency, making it crucial to choose suppliers with a strong reputation in the market.

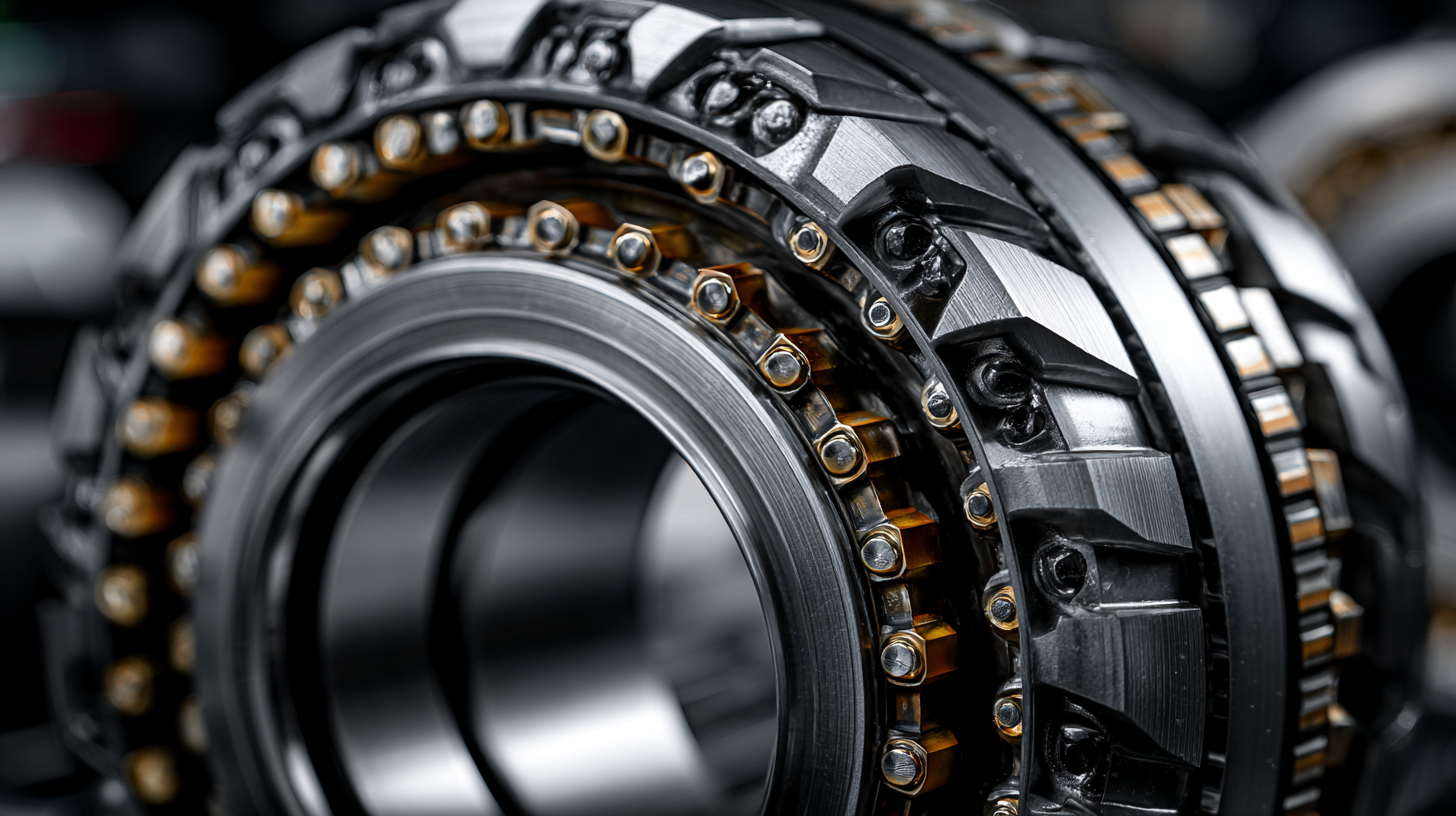

Global Market Trends in Cylindrical Roller Bearings (2023)

The chart above illustrates the growth in global sales of cylindrical roller bearings from 2019 to 2023, reflecting China's quality upgrades and dominance in this sector. The trend showcases a significant increase in sales volume, indicating the rising demand for high-quality bearings worldwide.

The Impact of Quality Improvements on China's Bearing Industry Performance Metrics

China's cylindrical roller bearing industry has undergone significant quality upgrades in recent years, reflecting a strategic shift towards excellence in manufacturing standards. These improvements have not only elevated product performance but have also enhanced overall industry performance metrics. As manufacturers invest in advanced technologies and stringent quality control protocols, the reliability and durability of Chinese bearing products have gained international recognition, driving global sales success.

The impact of these quality enhancements is evident in various performance metrics such as production efficiency, customer satisfaction, and market share. Improved production techniques have led to reduced defect rates and shorter lead times, allowing companies to meet the growing demands of global markets.

Moreover, enhanced product quality has resulted in higher customer loyalty and an increasing number of repeat orders, solidifying China's position as a key player in the global bearing industry. As a result, Chinese manufacturers are not only meeting domestic needs but are also successfully penetrating international markets, showcasing the profound impact of quality improvements on their performance.

Case Studies: Successful Global Sales Strategies in Cylindrical Roller Bearings

As China's production capabilities for cylindrical roller bearings continue to improve, companies are leveraging innovative global sales strategies to capitalize on this quality upgrade. Success in this market hinges on understanding diverse consumer needs and establishing robust distribution networks. For instance, utilizing content marketing can drive brand awareness and showcase product reliability, aligning with the increasing global e-commerce trends.

Tip 1: To effectively reach international customers, consider creating localized content that resonates with specific markets. Highlighting case studies of successful implementations can build trust and demonstrate the effectiveness of your products in varied applications.

Collaborating with industry influencers can amplify your brand message and extend your reach. This strategy not only enhances brand credibility but also taps into the established audiences of these influencers, facilitating more effective communication and engagement.

Tip 2: Actively utilize platforms like social media and professional networks to identify and engage potential brand ambassadors within the industry. This can lead to valuable partnerships that boost visibility and foster customer loyalty.

Technological Innovations Driving Quality Upgrades in China's Manufacturing Sector

In recent years, China's manufacturing sector has experienced a remarkable transformation fueled by technological innovations. Notably, the cylindrical roller bearing industry has witnessed significant advancements that enhance quality and reliability. By incorporating cutting-edge technologies such as smart manufacturing systems, automation, and advanced materials, Chinese manufacturers are not only improving product performance but also meeting stringent international standards. This evolution is essential for competing in the global market, as quality has become a top priority for buyers around the world.

Moreover, these innovations have enabled Chinese manufacturers to streamline their production processes, leading to increased efficiency and reduced production costs. The adoption of Industry 4.0 principles, including the Internet of Things (IoT) and data analytics, allows for real-time monitoring and optimization of manufacturing operations. As a result, companies can respond swiftly to changes in demand and enhance their product offerings. Ultimately, this focus on quality and technological advancement is driving the global sales success of China's cylindrical roller bearings, positioning the country as a formidable player in the global manufacturing arena.

Future Projections: China's Role in the Global Bearings Market through 2025 and Beyond

As we look ahead to 2025 and beyond, China's influence in the global bearings market is projected to expand significantly. With advancements in manufacturing technology and a commitment to quality upgrades, Chinese cylindrical roller bearings are set to drive substantial gains in market share. The global bearings market is evolving, with key segments such as automotive, aerospace, and industrial applications experiencing increased demand. The push for innovation and efficiency from Chinese manufacturers positions them favorably to meet these diverse needs and elevate their status on the world stage.

In tandem with this growth, other sectors, like the knee replacement market, are also experiencing remarkable expansions. Projected to reach $8.96 billion in value by 2024 and grow to $13.17 billion by 2032, the compound annual growth rate of 5.0% underlines the increasing importance of high-quality components in medical applications. As China continues to invest in renewable energy, particularly winde energy with an expected annual increase of over 70 million kilowatts, the synergy between high-quality bearing production and other high-demand sectors will further bolster the country’s position in the global supply chain, paving the way for unprecedented economic opportunities.