10 Best High Speed Ball Bearings for Ultimate Performance in 2023

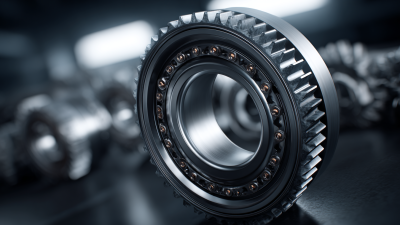

In the realm of mechanical engineering and performance optimization, high speed ball bearings stand out as crucial components that significantly enhance efficiency and durability. As technology advances, the demand for bearings that can handle higher speeds and loads, while minimizing friction and heat generation, has never been greater. This is particularly evident in industries such as robotics, automotive, and aerospace, where the quest for ultimate performance drives innovation and design.

Selecting the right high speed ball bearings is essential for achieving peak performance and reliability in various applications. With numerous options available in the market, it can be challenging to identify the best bearings that meet specific requirements. This article aims to explore the ten best high speed ball bearings of 2023, analyzing their features and benefits to help you make informed decisions. Whether you are a professional engineer or an enthusiastic hobbyist, understanding the critical role of these bearings can lead to improved functionality and longevity in your projects.

Top Considerations for Choosing High Speed Ball Bearings

When choosing high-speed ball bearings, several critical considerations can significantly impact performance and longevity. First, the material composition plays a pivotal role. Most high-speed bearings are fabricated from stainless steel, ceramic, or hybrid materials, each offering distinct benefits. According to a report by the International Journal of Engineering Research and Applications, ceramic bearings provide lower friction and enhanced wear resistance, making them ideal for extreme-speed applications where heat generation is a concern.

Another essential factor is the bearing's lubrication. The type of lubricant used can substantially affect the bearing's speed capabilities and lifespan. High-speed applications often require low-viscosity lubricants to minimize drag and heat buildup, as indicated by the Society of Tribologists and Lubrication Engineers. Additionally, proper sealing mechanisms are crucial; bearings with robust seals can prevent contaminants from entering while maintaining lubricant integrity, which is vital for reducing frictional wear and ensuring optimal performance under demanding conditions.

Finally, the design and tolerance of the bearings are significant. Precision-engineered bearings with tighter tolerances can facilitate smoother operation at high speeds, as shown in research published by the American Society of Mechanical Engineers. Selecting the right bearing involves a careful balance of these factors to achieve the desired performance in any high-speed application.

Key Features of High Speed Ball Bearings for Enhanced Performance

High-speed ball bearings play a crucial role in maximizing the efficiency and performance of machinery across various applications. One of the key features to consider is the material composition of the bearings. High-quality materials, such as stainless steel or ceramic, offer superior durability and resistance to wear, which results in smoother operation and reduced friction. Additionally, advanced heat treatment and surface finishing techniques can enhance the load-bearing capacity and prolong the lifespan of the bearings, making them ideal for high-speed applications.

Another important aspect of high-speed ball bearings is their precision and tolerance levels. Precision manufacturing ensures that the bearing components fit together seamlessly, minimizing vibrations and enhancing stability during operation. Tolerances are typically classified into different grades, with tighter tolerances yielding better performance at increased speeds. Furthermore, the type of lubricant used in these bearings can significantly affect their performance. High-speed lubricants, often specifically formulated for reduced friction and heat retention, are essential for maintaining optimal operating conditions and extending the service life of the bearings.

Popular Materials Used in High-Speed Ball Bearings Manufacturing

High-speed ball bearings play a crucial role in various applications, from automotive to aerospace, where performance is paramount. The materials used in their manufacturing significantly affect their efficiency and durability. Common materials include chrome steel, stainless steel, ceramic, and hybrid combinations. According to a report by the American Bearing Manufacturers Association, nearly 70% of ball bearings in high-speed applications utilize chrome steel due to its excellent hardness and wear resistance. This alloy is capable of withstanding high centrifugal forces while maintaining low friction, making it ideal for high-performance systems.

Stainless steel is another popular choice, particularly when corrosion resistance is needed. It offers a balance of strength and durability, which is critical in environments exposed to moisture or harsh chemicals. A study published in the Journal of Materials Science highlights that stainless steel bearings can maintain their integrity and performance even after prolonged exposure to challenging conditions, making them suitable for both industrial machinery and consumer electronics. Moreover, the rise of ceramic materials has introduced a new standard in bearing technology. Ceramics boast superior hardness and thermal stability, enabling them to function effectively at higher speeds and temperatures. Research indicates that hybrid bearings, which combine ceramic balls with steel rings, can reduce friction by up to 30%, enhancing the overall performance in high-speed scenarios.

10 Best High Speed Ball Bearings for Ultimate Performance in 2023

| Size (mm) |

Material |

Max RPM |

Load Rating (N) |

Application |

| 10 x 5 x 5 |

Ceramic |

40,000 |

50 |

Drones |

| 15 x 6 x 5 |

Stainless Steel |

30,000 |

70 |

Electric Motors |

| 12 x 8 x 3 |

Hybrid |

35,000 |

60 |

Robotics |

| 8 x 4 x 2.5 |

Ceramic |

50,000 |

40 |

RC Cars |

| 20 x 10 x 5 |

Stainless Steel |

25,000 |

90 |

Industrial Machinery |

| 16 x 6 x 6 |

Titanium |

28,000 |

80 |

Bicycles |

| 25 x 12 x 6 |

Carbon Steel |

22,000 |

100 |

CNC Machines |

| 30 x 15 x 7 |

Aluminum |

20,000 |

110 |

Conveyor Systems |

| 18 x 9 x 4 |

Composite |

27,000 |

75 |

Fans and Blowers |

| 22 x 10 x 5 |

Nylon |

24,000 |

65 |

Robotics and Automation |

Comparison of Leading Brands in the High Speed Ball Bearings Market

In the competitive landscape of high speed ball bearings, manufacturers are continuously striving to enhance performance, durability, and efficiency. Leading brands are harnessing advanced materials and engineering techniques to optimize their products. According to a recent market analysis by Research and Markets, the global ball bearing market is expected to reach $18 billion by 2025, driven by increasing demand from industries like automotive and aerospace. High speed ball bearings, in particular, are seeing a surge in popularity due to their ability to reduce friction and enhance operational speeds, which can lead to significant energy savings.

Comparative studies indicate that high speed ball bearings vary widely in terms of construction, lubrication methods, and design features. For instance, the use of ceramic materials alongside traditional steel is becoming more common, with reports showing that ceramic high speed ball bearings can improve performance by up to 20% in certain applications. Additionally, the introduction of advanced lubrication technologies, such as grease and oil with superior thermal stability, further indicates the commitment of manufacturers to provide more efficient solutions to meet the evolving demands of high-speed machinery. As industries continue to push boundaries, the performance of high speed ball bearings will play a pivotal role in equipment reliability and overall operational success.

Maintenance Tips for Longevity of High Speed Ball Bearings

When it comes to high-speed ball bearings, proper maintenance is essential to ensure optimal performance and longevity. According to industry research, the reliability of these components is significantly influenced by their maintenance routines. Regular inspection and cleaning can prevent damage from contaminants, which is one of the leading causes of bearing failure in high-speed applications. Implementing a maintenance schedule that includes lubrication checks can help maintain the integrity of the lubricant, which acts as a barrier against friction and wear. Reports from international mechanical engineering societies indicate that improper lubrication can reduce the lifespan of bearings by as much as 30%.

Additionally, monitoring operating conditions is vital for sustaining high-speed performance. Factors such as temperature fluctuations and load variations can directly impact bearing efficiency. Data from bearing maintenance studies reveal that keeping the operating temperature within manufacturer-recommended limits can enhance the lifespan of bearings, with a researched average increase of up to 50% in high-performance settings. Furthermore, using vibration analysis and advanced monitoring technologies can help in predicting maintenance needs, thereby reducing unexpected failures related to wear and tear. Proper maintenance not only boosts performance but also extends the service life of high-speed ball bearings, making it a critical focus for engineers and technicians in the field.