Best Large Bearings for Heavy Machinery Applications?

In the realm of heavy machinery, large bearings play a critical role. These components ensure the smooth operation of machinery under immense loads. High-quality large bearings can enhance efficiency and reduce maintenance costs.

Heavy machinery often faces harsh conditions. Dust, moisture, and vibrations test the durability of bearings. Choosing the right large bearings can prevent frequent breakdowns. This decision requires careful consideration of material and design.

Some may overlook the importance of large bearings. They might focus solely on machinery aesthetics or performance metrics. However, neglecting bearing quality can lead to significant operational issues. Finding the best large bearings is crucial for reliability in heavy machinery applications. Balancing cost and performance is a challenge that requires attention.

Best Large Bearings for Heavy Machinery Applications

When selecting large bearings for heavy machinery applications, several factors come into play. The load conditions are crucial; these bearings must bear significant weight. They also face different stresses from vibrations and shock loads. Choosing the right material is essential. Steel is common, but some applications require additional corrosion resistance.

Maintenance plays a vital role in the longevity of these bearings. Regular check-ups can prevent unexpected failures. However, many overlook this crucial step. Signs of wear include unusual noises or vibrations. Addressing these issues promptly can save time and resources in the long run.

Installation accuracy is equally important. Misalignment can lead to premature wear. Even slight deviations may result in operational inefficiency. It’s easy to dismiss this aspect, but it requires careful attention. The benefits of thorough installation often outweigh the initial effort. Remember to evaluate the surroundings and operating conditions as well. Ensuring proper lubrication enhances performance and reduces friction. This seemingly simple step is sometimes neglected, leading to costly errors.

Types of Large Bearings Used in Heavy Machinery

Large bearings are essential components in heavy machinery. They support substantial loads and help in efficient operation. Typically, these bearings come in various types, each suited for specific applications.

Roller bearings, for example, are commonly used for their ability to withstand high radial loads. They excel in tasks that require durability and strength.

Another type is the spherical bearing. This variant is designed to accommodate misalignment, making it useful in machinery that undergoes significant movement.

There are also split bearings. These are convenient for maintenance, as they can be assembled without disassembling adjacent equipment. However, they might not always provide the same rigidity as traditional options.

In heavy machinery, choosing the right bearing is crucial. A wrong choice can lead to failures, causing downtime and increased costs. Sometimes the best solutions aren’t immediately obvious.

Observations from the field show that factors like load, speed, and environmental conditions must be carefully considered. Operators need to balance strength with maintenance needs. Regular checks and updates can help avoid bigger issues down the line.

Industry Standards and Specifications for Large Bearings

In heavy machinery applications, large bearings play a critical role. Their performance is determined by various industry standards and specifications. These standards ensure reliability and durability under extreme conditions. For instance, the American National Standards Institute (ANSI) outlines specific load ratings. This is essential for applications in construction and mining.

Research from the Equipment Manufacturer Association (EMA) highlights trends in bearing materials. High-strength steel and composite materials are increasingly prevalent. They provide better wear resistance, which is key for heavy loads. However, not all bearings meet the required specifications. This can lead to premature failures. Regular testing and adherence to ISO standards are crucial.

Moreover, lubrication practices significantly impact bearing lifespan. The use of appropriate greases reduces friction and heat. The National Lubricating Grease Institute (NLGI) recommends specific grease types for various temperatures. It's essential to consider environmental factors as well. Incomplete sealing can allow contaminants to enter, compromising performance. Reflecting on these factors can lead to better decisions in the procurement and maintenance of large bearings.

Best Large Bearings for Heavy Machinery Applications

| Bearing Type |

Load Capacity (kN) |

Diameter (mm) |

Speed Rating (rpm) |

Material |

| Spherical Roller Bearing |

2000 |

200 |

1500 |

Steel |

| Tapered Roller Bearing |

2500 |

220 |

1200 |

Alloy Steel |

| Cylindrical Roller Bearing |

1500 |

180 |

1800 |

Chrome Steel |

| Deep Groove Ball Bearing |

1000 |

160 |

2000 |

Stainless Steel |

| Self-Aligning Ball Bearing |

1200 |

190 |

1600 |

Steel |

Market Trends and Innovations in Bearing Technologies

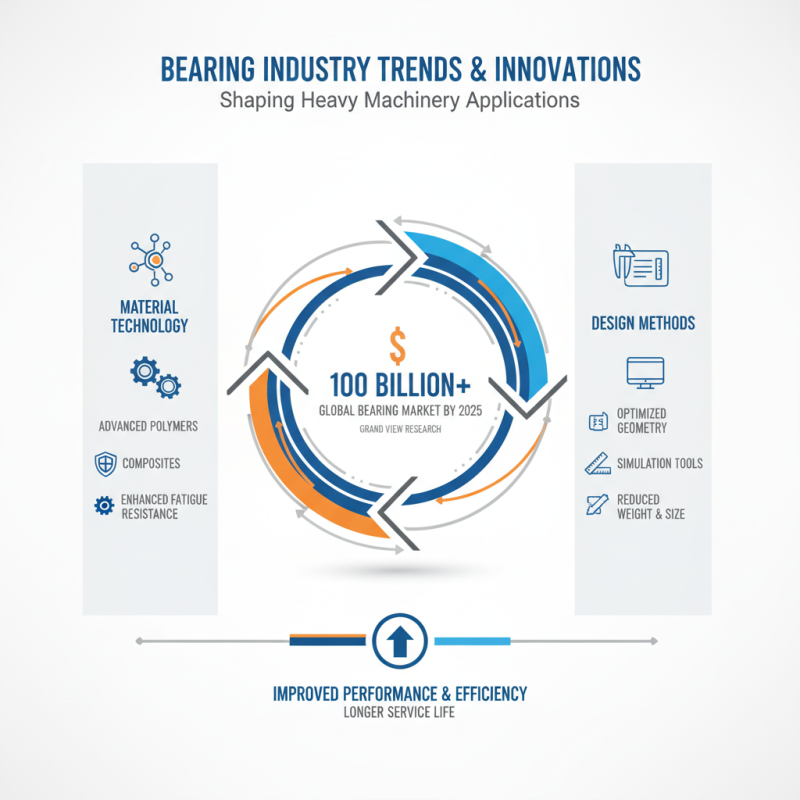

The bearing industry is witnessing significant trends and innovations, shaping heavy machinery applications. According to a recent market report by Grand View Research, the global bearing market is projected to reach over $100 billion by 2025. Advancements in material technology and design methods are driving this growth. New materials, such as advanced polymers and composites, enhance fatigue resistance and reduce overall weight. This leads to improved performance and efficiency.

In heavy machinery, the demand for larger bearings is rising. Larger bearings can handle greater loads. However, larger does not always mean better. Engineers must consider load distribution and wear. Innovations in lubrication are also crucial. Increased lubrication efficiency can extend bearing life. Smart lubrication systems are becoming more common, automatically adjusting based on operational conditions.

**Tip 1:** Regular maintenance is key. Inspect bearings frequently for wear signs. Catching issues early can save costs.

**Tip 2:** Choose the right materials. The environment plays a significant role. Corrosive conditions can shorten bearing life.

According to studies, integrating IoT technology into bearings is on the rise. Smart bearings can monitor conditions in real-time. This proactive approach can lead to significant operational savings. Still, the integration of technology needs careful planning. Understanding the impact on existing systems is essential.