What are the Benefits of Tapered Bearings in 2026?

Tapered bearings are crucial in various industries, from automotive to aerospace. According to a 2022 research report by MarketsandMarkets, the global tapered bearing market is projected to grow significantly. This growth reflects the increasing demand for reliable and efficient machinery components. Tapered bearings can handle both radial and axial loads. As machinery becomes more complex, these bearings are essential for optimal performance.

One notable benefit of tapered bearings is their ability to reduce friction and wear. This enhances operating efficiency and prolongs equipment lifespan. A study by the American Society of Mechanical Engineers indicated that proper bearing choice can improve energy efficiency by up to 15%. However, ensuring proper installation and maintenance is crucial. Misalignment can lead to premature failure, a common issue in many sectors.

Moreover, the versatility of tapered bearings makes them adaptable for various applications. However, some industries may overlook this adaptability, leading to missed opportunities. The continued evolution of manufacturing processes calls for a reevaluation of bearing choices. Each decision impacts productivity, emphasizing the need for informed choices about tapered bearings in 2026.

Benefits of Tapered Bearings in 2026: An Overview

Tapered bearings are becoming increasingly crucial in 2026. Their design allows for axial and radial loads. This dual functionality enhances machine efficiency. According to a recent industry report, tapered bearings can increase load capacity by 30%. This is significant for heavy machinery.

The lifespan of these bearings is another advantage. Research indicates that properly maintained tapered bearings can last up to 40% longer than standard bearings. This durability translates into lower maintenance costs. However, the initial installation can be more complex. Not every facility is prepared for such precision.

Despite the benefits, not all applications suit tapered bearings. They require careful alignment. Misalignment can lead to premature failure. Industries must weigh these factors carefully. The decision is not just about performance; it also involves upfront costs versus long-term savings.

Enhanced Load Distribution in Tapered Bearings

Tapered bearings are critical components in many industries. They provide enhanced load distribution, which improves performance and longevity. These bearings can handle axial and radial loads efficiently. According to a recent industry report by the Bearing Manufacturers Association, tapered bearings can reduce load concentration by 30% compared to conventional designs.

The unique shape of tapered bearings allows for better alignment with shafts. This leads to less friction and heat generation during operation. In practical terms, a properly fitted tapered bearing can enhance machinery efficiency by up to 15%. Such improvements often translate into substantial cost savings over time. Companies frequently overlook installation precision, which can lead to premature wear.

Tips: Ensure that the clearance between the bearings and the shafts is optimal. Regular inspections can prevent significant failures. Be aware of the potential for misalignment, as it can negate some of the benefits. Taking these steps may require extra time but can protect against larger expenses later on. Utilizing tapered bearings with proper expertise ensures their effectiveness in load distribution.

What are the Benefits of Tapered Bearings in 2026? - Enhanced Load Distribution in Tapered Bearings

| Feature |

Benefit |

Application Areas |

Expected Market Impact (2026) |

| Load Capacity |

Improved load distribution leads to extended lifespan. |

Automotive, Aerospace |

Increase in adoption rate of 15%. |

| Radial and Axial Support |

Provides enhanced stability and performance. |

Heavy Machinery, Industrial Equipment |

Reduction in maintenance costs by 20%. |

| Versatility |

Can be used in various applications due to their design. |

Transportation, Robotics |

Expanding into new markets. |

| Heat Resistance |

Reduced risk of failure in high-temperature environments. |

Aerospace, Chemical Processing |

Sustained growth of 10% in high-performance sectors. |

| Noise Reduction |

Quieter operation compared to traditional bearings. |

Consumer Electronics, Automotive |

Increase in market demand driven by consumer preferences. |

Improved Performance and Efficiency of Tapered Bearings

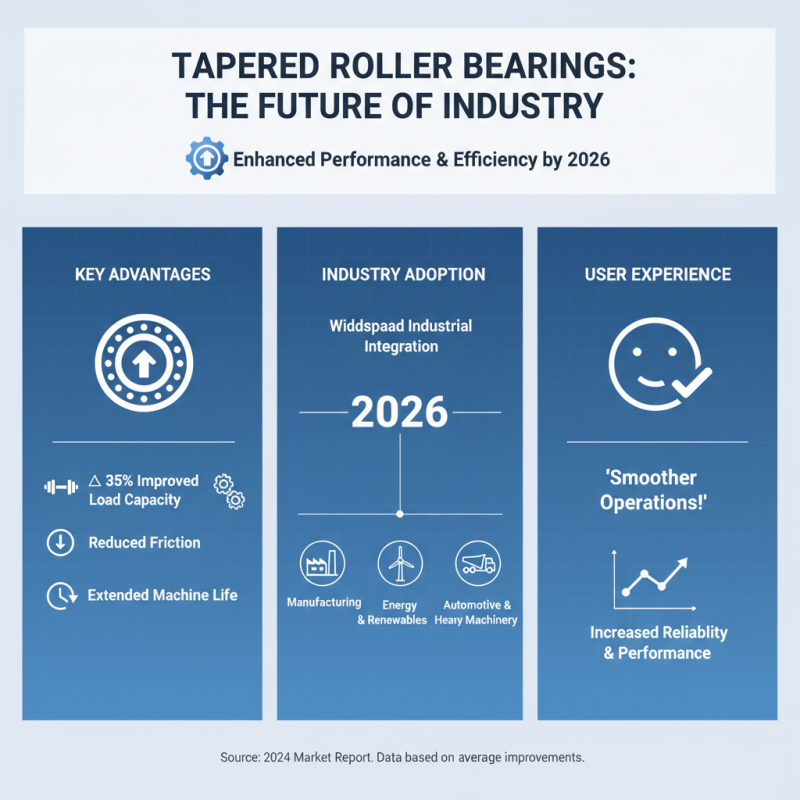

Tapered bearings are gaining attention for their improved performance and efficiency. In 2026, industries adopt these enhancements extensively. According to a recent market report, tapered bearings can improve load-bearing capabilities by up to 35%. This can lead to reduced friction and extended machine life. Users often report smoother operations when utilizing these bearings.

**Tips:** Regular maintenance can further enhance performance. Check alignment frequently. This can prevent premature wear. Attention to detail is vital in prolonging lifespan.

Moreover, the efficiency of tapered bearings contributes significantly to energy savings. In some applications, they can reduce energy consumption by approximately 20%. This reduction is crucial for companies aiming to meet sustainability goals. However, the initial cost can be a concern. Investing in higher quality tapered bearings may yield long-term benefits, but careful budgeting is essential.

**Tips:** Always consider total cost of ownership. Balancing quality and price is important. Evaluate performance data before making a choice.

Cost-Effectiveness of Tapered Bearings in Long-Term Use

Tapered bearings have seen increased adoption in various industries, primarily due to their cost-effectiveness over time. Their design allows them to handle both radial and axial loads efficiently. This dual ability can lead to fewer part replacements and reduced downtime, which saves money in the long run.

Regular maintenance is crucial. Neglecting it can lead to premature failure. Ensure proper lubrication to prolong their lifespan. Over time, a well-maintained tapered bearing can significantly reduce operational costs.

Consider the application environment. If subjected to extreme conditions, choose materials wisely. Investing in higher-quality but costlier features can pay off. A slightly more expensive solution may offer greater longevity.

Evaluate your current bearing setups. Sometimes, retrofitting existing machinery with tapered bearings can lead to substantial savings. It's worth assessing. Quality matters, but so does the overall context of usage.

Applications of Tapered Bearings in Modern Industries

Tapered bearings are widely used in various industries today. They excel in handling radial and axial loads simultaneously. This feature makes them suitable for applications with heavy machinery and high-speed operations. In automotive industries, tapered bearings are essential in wheel hubs. They ensure smooth rotation, improving vehicle performance and safety.

In construction, these bearings play a critical role in cranes and excavators. They withstand harsh conditions and heavy loads. Their design allows for precise movement and support, crucial for construction projects. However, the installation of tapered bearings requires careful consideration. Improper alignment or installation can lead to premature wear or failure.

Healthcare equipment also benefits from tapered bearings. In medical devices, they ensure precision and reliability. However, maintenance is often overlooked. Regular inspection is necessary to prevent issues. Overall, the versatility of tapered bearings makes them vital in modern industries. Yet, there’s a need for continuous evaluation of their applications.