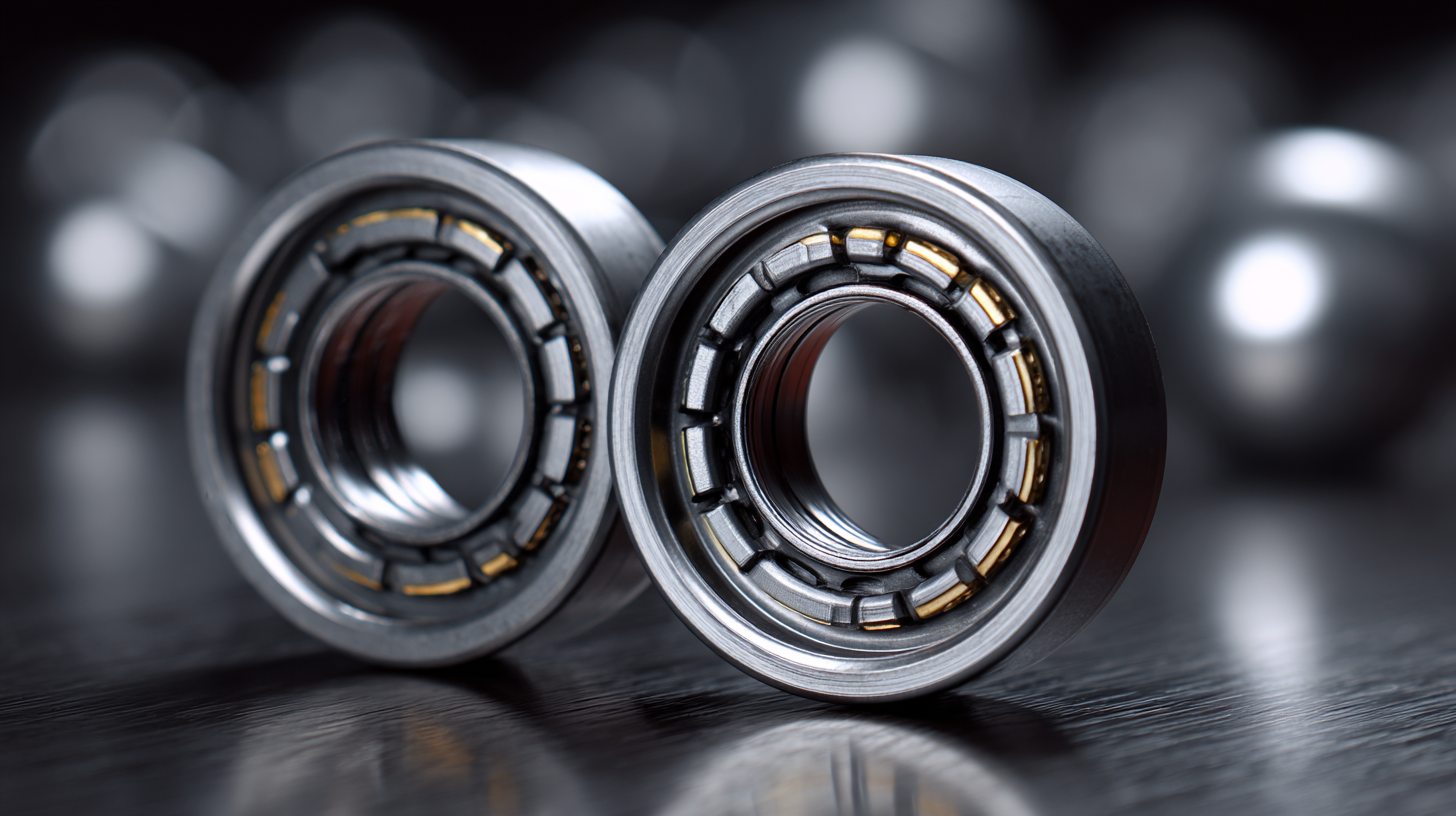

In today’s increasingly interconnected economy, global sourcing strategies for spherical ball bearings have become crucial for optimizing supply chain efficiency. With the ball bearing market expected to grow significantly, reaching an estimated USD 33.24 billion by 2035, businesses are recognizing the importance of leveraging global resources to secure high-quality bearings at competitive prices. This trend allows manufacturers to remain agile and responsive to market demands while minimizing costs.

When considering global procurement for spherical ball bearings, companies should evaluate suppliers based on their production capabilities, quality certifications, and logistics efficiency. By collaborating with diverse suppliers across different regions, businesses can mitigate risks related to supply disruption and ensure a stable flow of materials.

Tips:

- Prioritize suppliers who demonstrate a commitment to quality and sustainability in their manufacturing processes.

- Develop strategic partnerships that not only focus on cost savings but also on innovation and technology sharing to stay ahead in the industry.

- Regularly assess market trends and forecasts, like those indicating growth in the motor bearing market, to align procurement strategies with emerging opportunities and challenges.